Company Profile

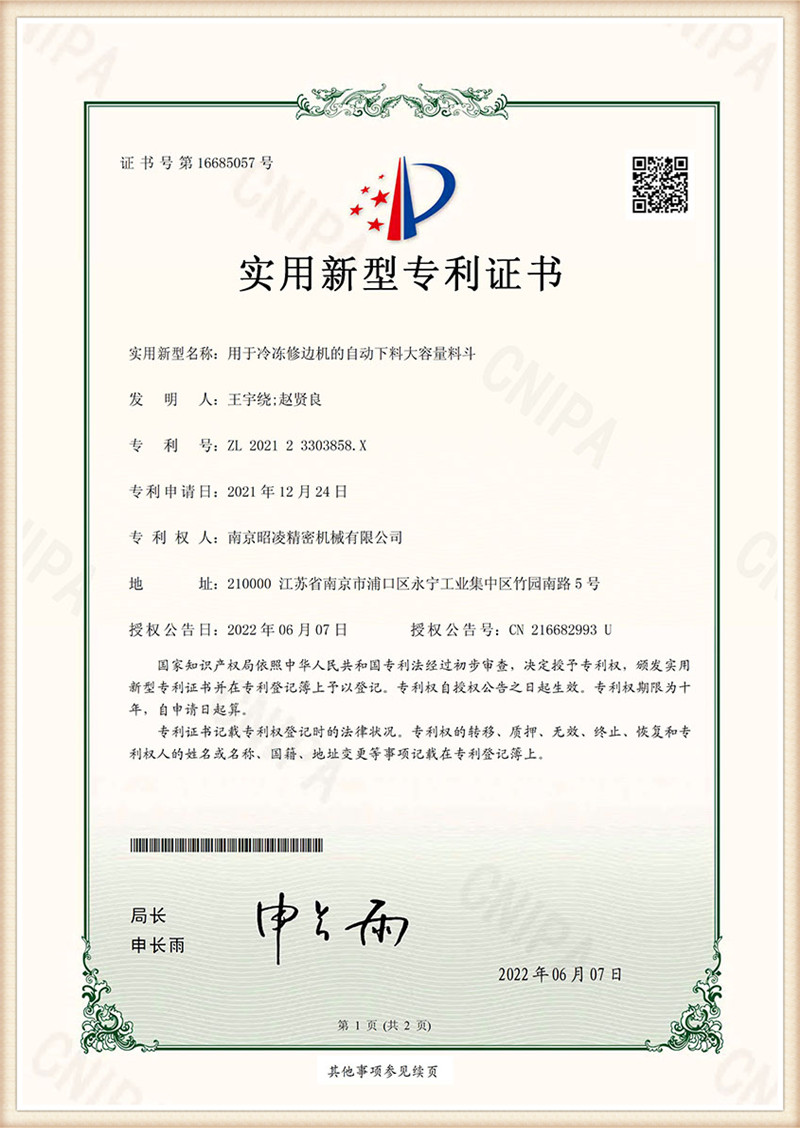

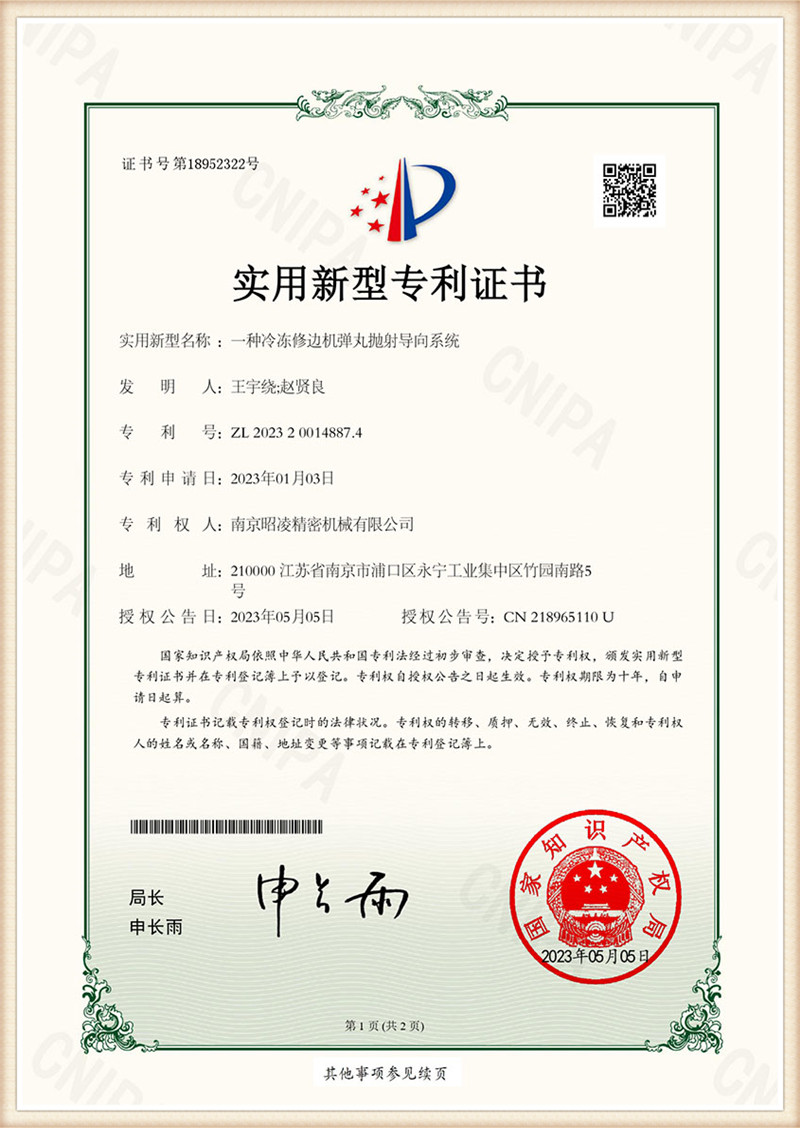

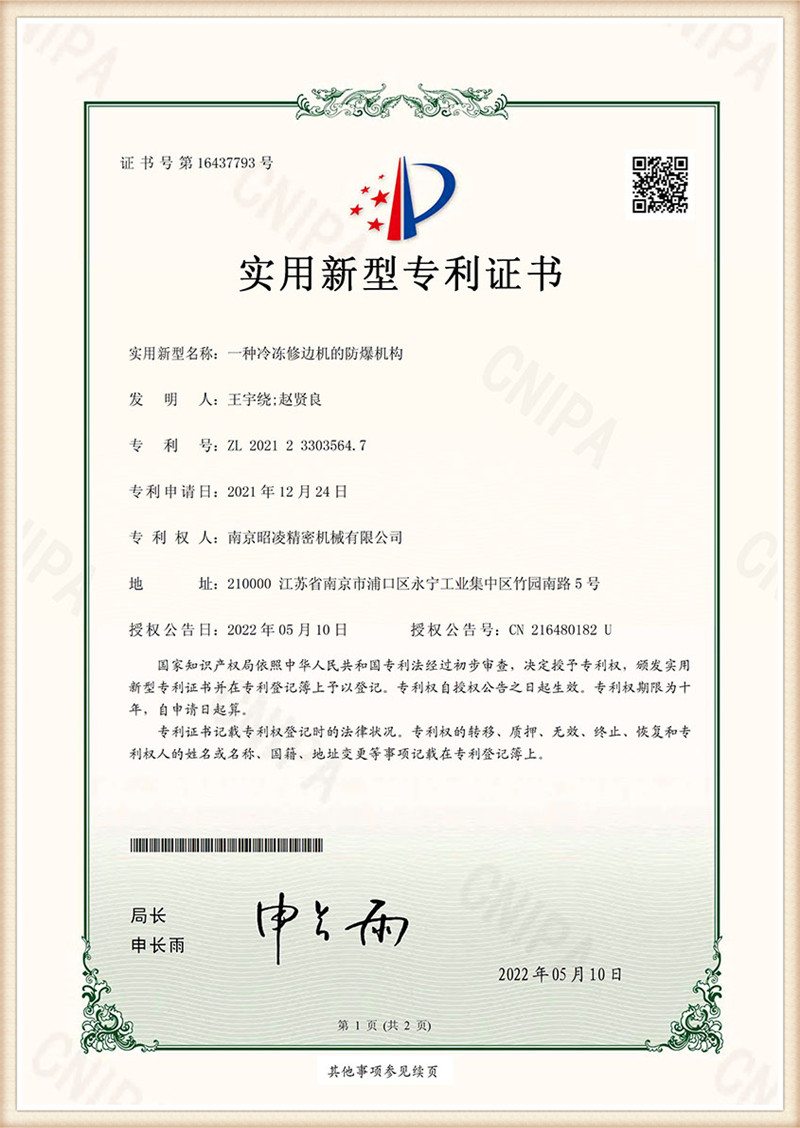

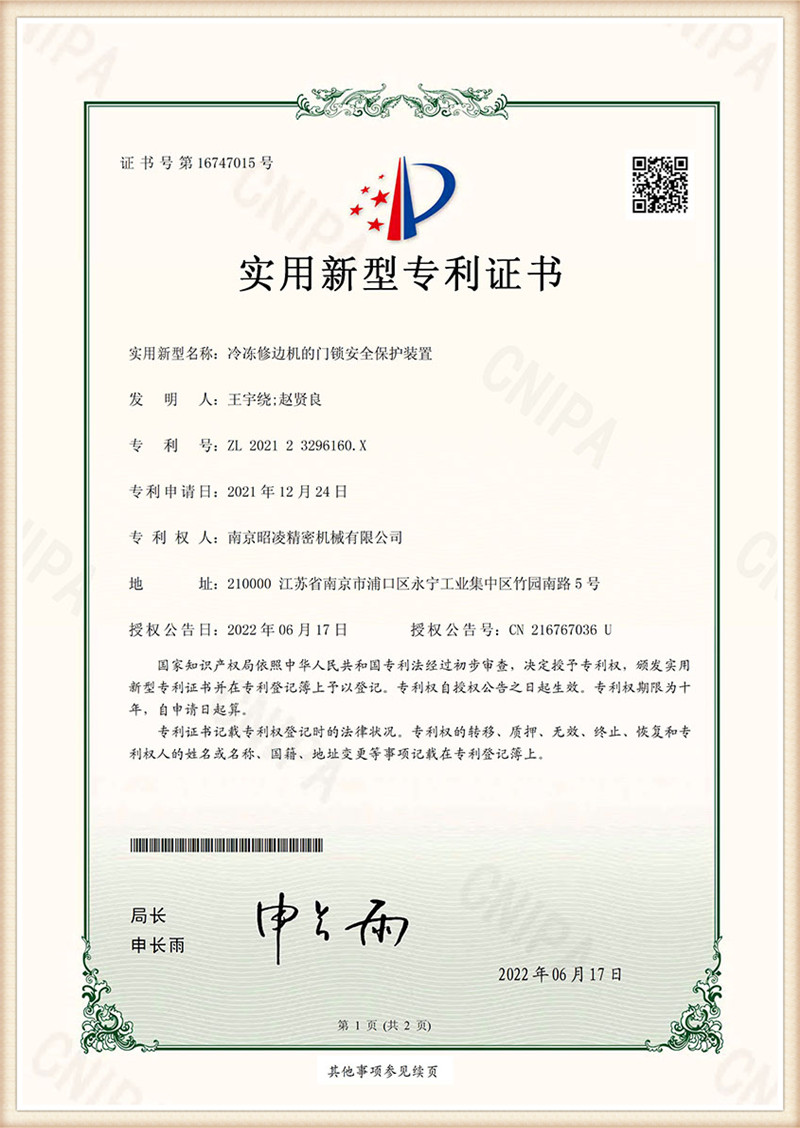

Showtop Techno-machine Nanjing Co., Ltd. is a national high-tech enterprise, for over 20 years STMC has been specializing in the R&D, manufacturing, sales & lifetime post-sales service, spare parts and consumable supplies of cryogenic deflashing machine and OEM service.

STMC has its global headquarter in Nanjing, China, south region subsidiary in Dongguan, West region subsidiary in Chongqing ,oversea branches in Japan and Thailand, committed to serving clients around the world.

.jpg)

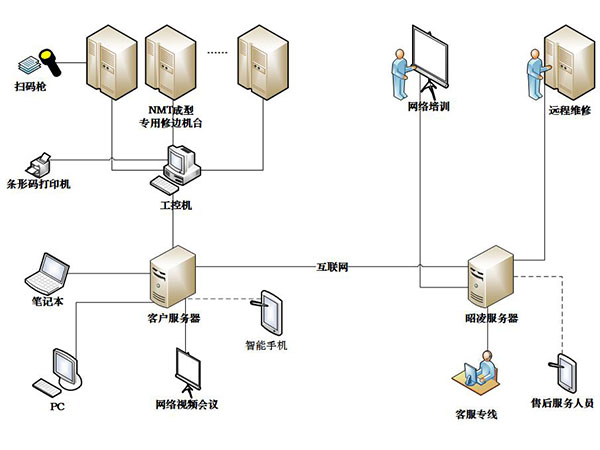

For clients that are preparing to apply cryogenic deflashing/deburring, STMC can provide process testing and professional analysis report for various products and provide viable plan & design base on the on-site condition.

STMC is able to arrange experienced engineers to provide on-site professional training and technical guidance for client operators regarding safe operation, parameter optimization, daily maintenance, and trouble shooting.

STMC has cryogenic deflashing/deburring process centers in East region(Nanjing), South region(Dongguan) and west region of China (Chongqing) to provide cryogenic deflashing testing and OEM services.

At the same time, STMC also provides machine renovation and upgrade service to various brands or specifications of cryogenic deflashing/deburing machine in order to help clients with machine-performance upgrade. And our corporate vision is to provide all customers with the best quality frozen edging machine.

Operation Process

1. Chooseing the type of cryogenic deflashing machine.

2. Confirm the operating temperature, projectile wheel speed, basket rotation speed and the processing time to remove the flash base on product condition.

3. Put in the first batch and appropriate amount of media.

4. Take out the processed product and put in the next batch.

5. To the end of processing.