Explosion-proof MG Series Cryogenic Deflashing/Deburring Machine

Detailed Display

Cryogenic deflashing machine MG-C

Cryogenic deflashing machine MG-T

Cryogenic deflashing machine core part options

Product Introduction

Advanced technology

1. Special designed for Magnesium alloy products deflashing, efficient burr removal, multiple safety protection, can easily handle complex structure of alloy die castings.

2. Enhance the surface oxidation resistance of the treated die-casting products and increase the working life of the product.

3. Reduce the production cost.

4. No damage to product surface, keep the appearance quality of the product.

5. Easy to operate and economic space occupation.

6. High deflashing accuracy and high pass rate of finished products.

Multiple safety protections

1. Automatic nitrogen injection system to make sure the oxygen level in chamber always below explosion limit.

2. The machine is equips oxygen sensor in order to measure and control the oxygen level.

3. The machine is anti-blast treated and equips safety pressure relief outlet at the top of the machine.

4. The machine compartment door is equipped with a pressure rod to resist the explosion impact.

Note

The oxygen level inside of the machine must be lower than 1.4% during the processing of magnesium die-castings products.

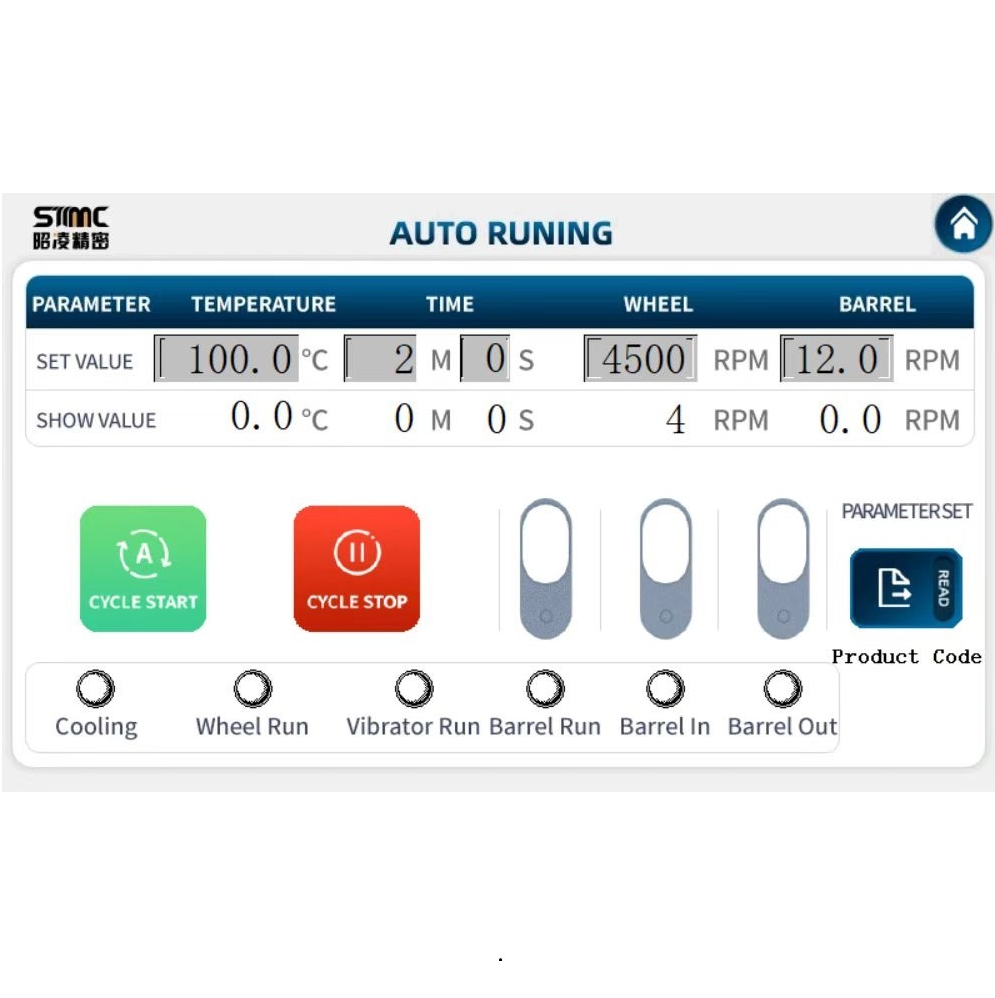

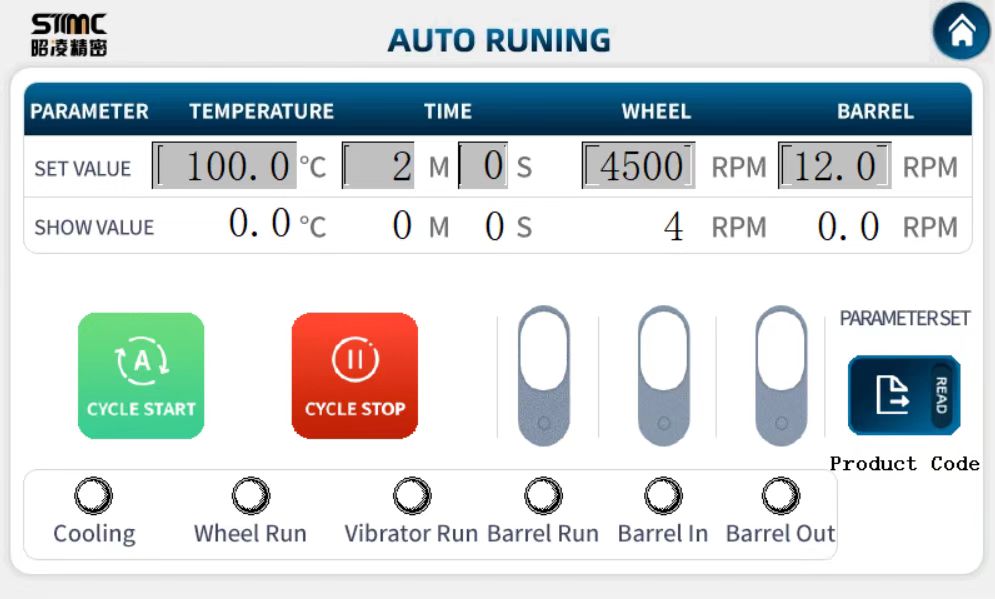

Operating Software Interface

Home Screen

Operating Main Screen

Automatic Mode

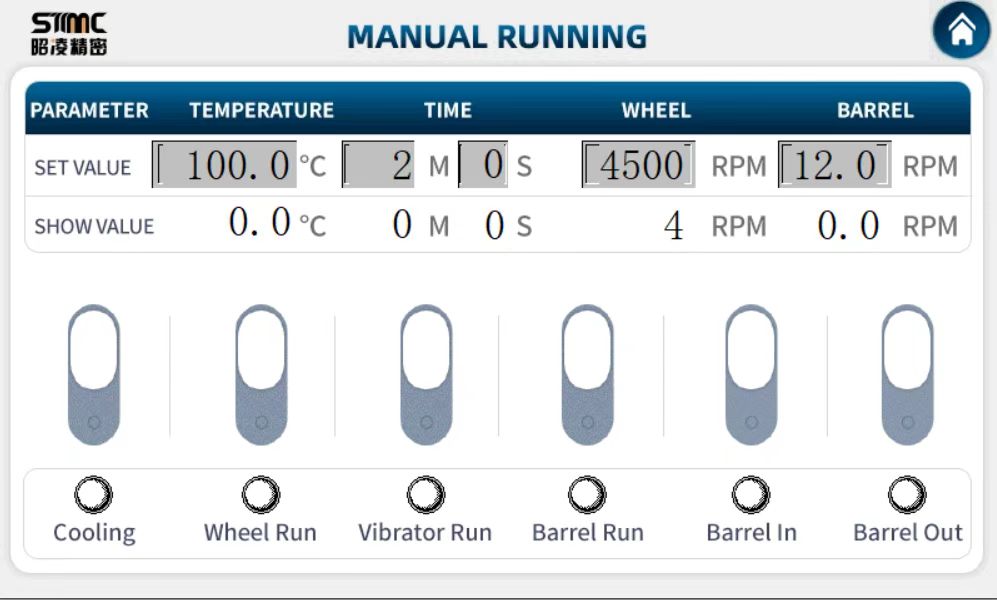

Manual Operating Mode

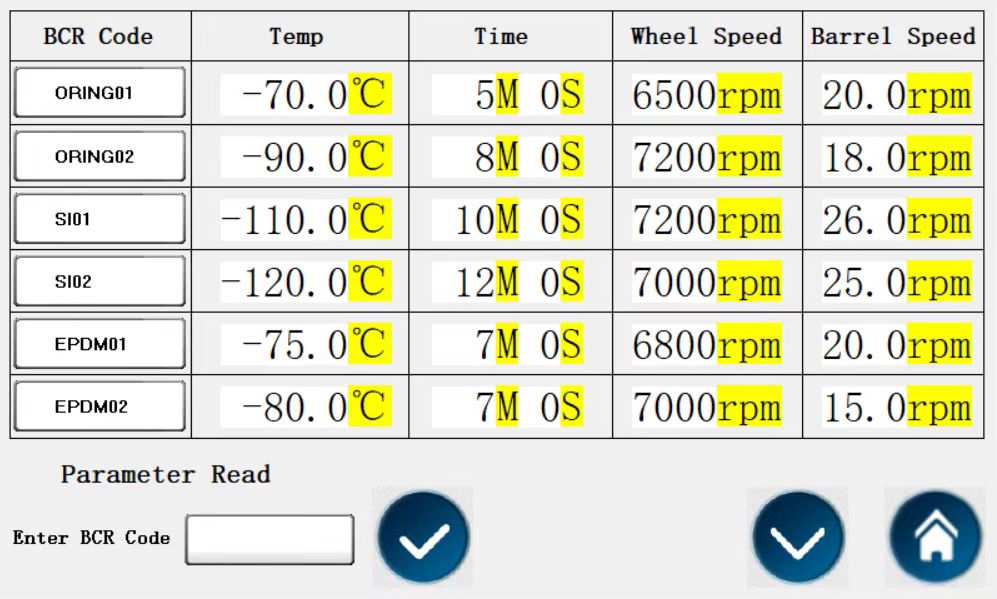

Parameter Save / Read

Parameter Library

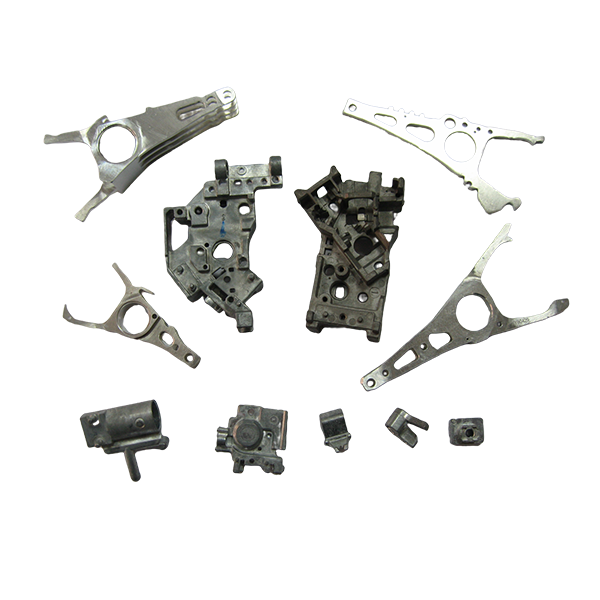

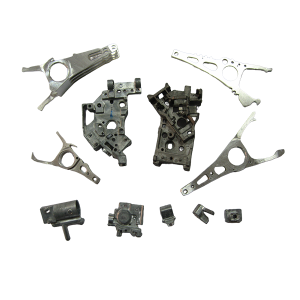

Application

Explosion-proof MG series cryogenic deflashing machine provides users with an efficient solution to deal with the flying edge of products. The explosion-proof special MG series refrigerated edging machine is customized to deal with magnesium alloy products, which can efficiently remove the flying edge of products without damaging magnesium alloy products and easily handle magnesium alloy products with complex structure.

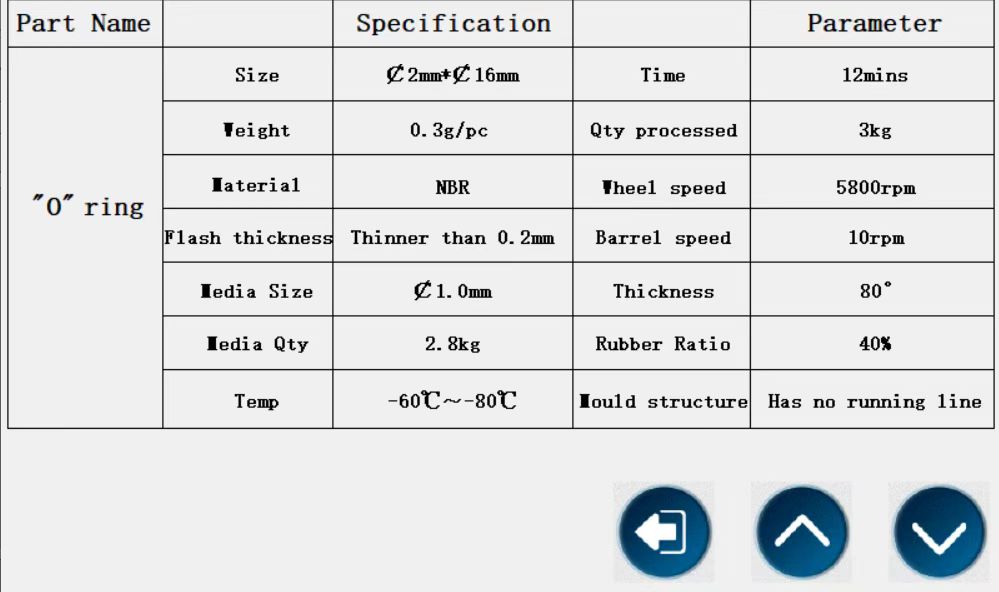

Products of Ultra Shot Series Cryogenic Deflashing Machine

Ultra Shot automatic jet cryogenic deflashing machine can accurately set the operating temperature, the projectile wheel speed, basket rotation speed and the processing time to remove the product flash according to the process needs; The program combination of solenoid valve and temperature regulator can automatically adjust the liquid nitrogen supply, so that the chamber is always at the optimum temperature for deflashing. The basket for containing products uses rotating + flipping design, which is convenient for operators to load and take materials and makes the deflashing process more effectively.