Ultra Shot Cryogenic Deflashing/Deburring Machine (Cryogenic Deflashing Machine Made in Japan)

Detailed Display

Japanese Made Cryogenic Deflashing Machine

Cryogenic deflashing machine core part options

Janpanese Made Cryogenic Deflashing Machine

Product Introduction

● The whole machine is original made in/imported from Japan.

● STMC provides pre-sales and post-sales service follow the standards and requirements of RESONAC Group.

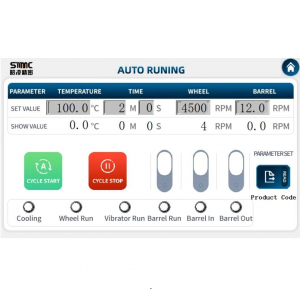

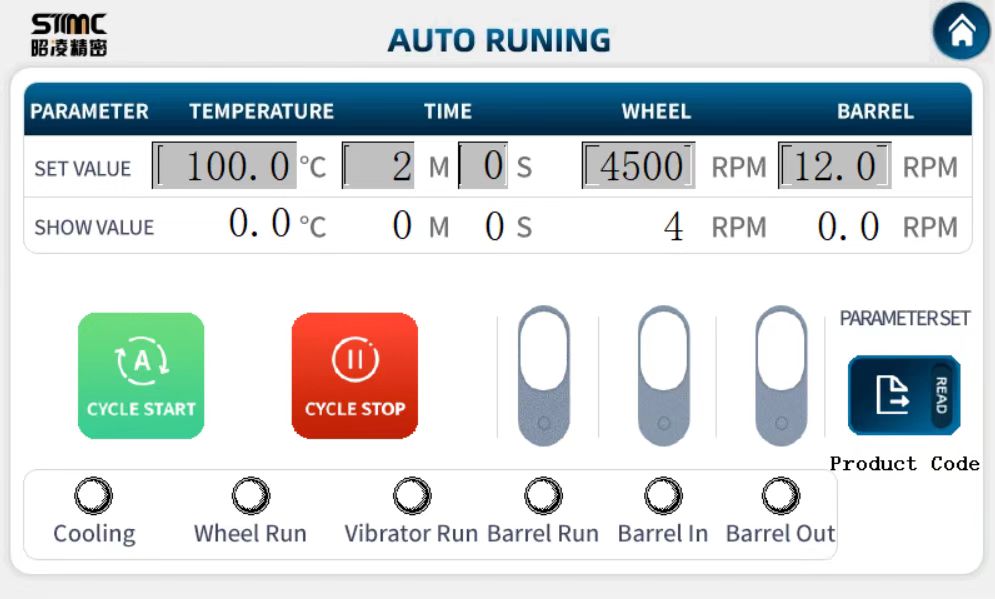

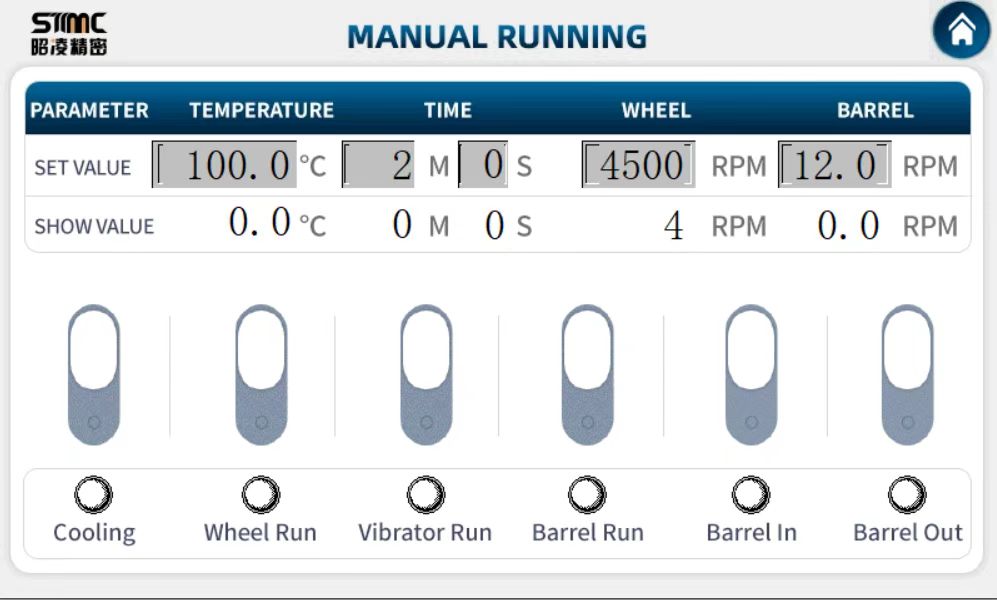

Operating Software Interface

Home Screen

Operating Main Screen

Automatic Mode

Manual Operating Mode

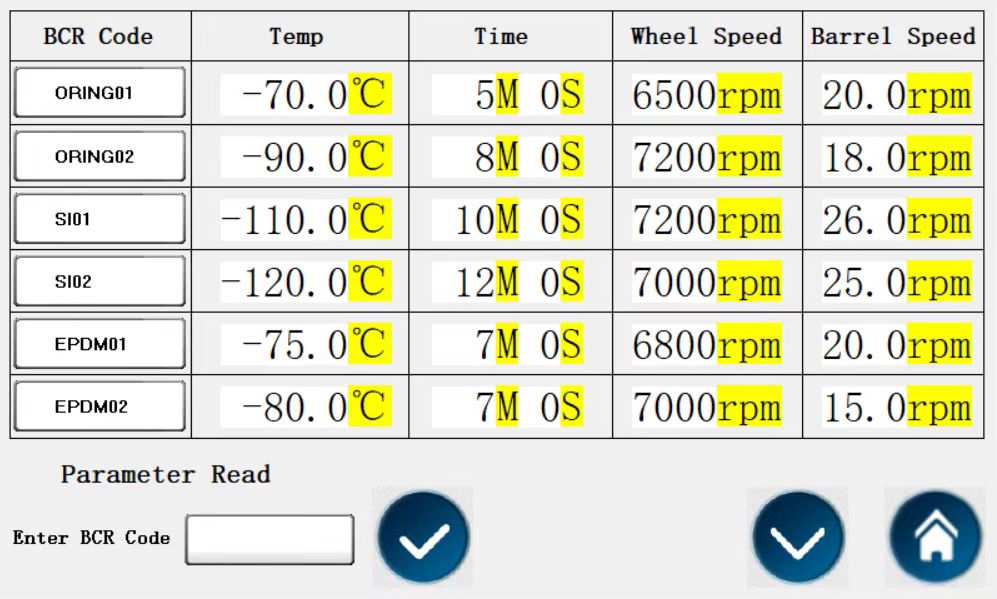

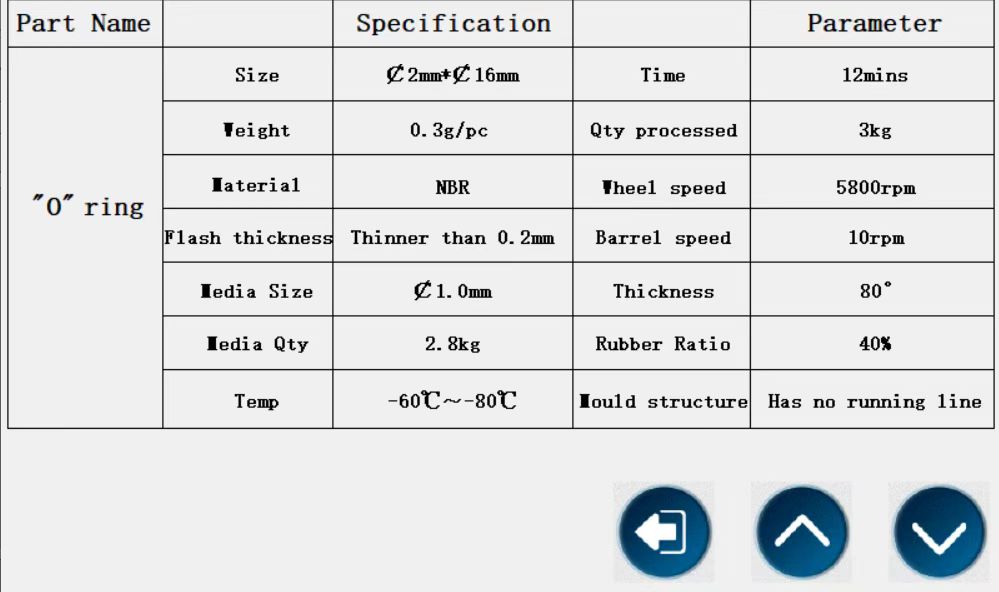

Parameter Save / Read

Parameter Library

Man-Machine Interaction & Control Systems

1. Easy-to-use large size colored touch screen operation interface, including multi-language support and QWERTY keyboard, making production faster and more consistent.

2. "One touch to start", enable mass parameter storage and reading, convenient and easy to manage.

3. With both manual and automatic operation mode, including routine maintenance check, password protection, processing list and screen diagnosis.

4. The automatic control system and interface of the machine can be customized according to clients needs and using habits.

5. Cloud platform monitoring available, enable real time monitoring and analyzing the usage and operating status of the machine.

Intelligent Manufacturing

In order to meet the operation requirements of digitization, information and intelligence, STMC is able to provide upgrades to the machines.

1. Set operation permission to avoid accidents caused by unauthorized personnel operating the machine.

2. Access and acquire the preinstalled parameters from the system by scanning the barcode. and synchronize the processing parameter record on both industrial control system and the machine.

3. The machine system has built-in operation guide and malfunction solution method, which can help the operators to find the problem more quickly through graphic information and automatically record the failure logging. At the same time, the screen will show the contact information of the manufacturer (STMC) for service.

Note: On the basis of this industrial control system, software itself can be further customized and developed (this part is not included in the quotation),in order to allow the data sharing between the equipment and the client's barcode system/MES system, therefore to realize the equipment access to the MES system and the equipment (production) on the cloud.