Recently, the technical laboratory at STMC successfully completed a cryogenic deburring test on a sample PBT (Polybutylene Terephthalate) + glass fiber reinforced injection molded component submitted by a client. The test results confirmed that the advanced Cryogenic Deflahing Machine effectively and completely removed micro burrs and flash from the part’s surface and internal holes. The significant outcome has garnered high approval from the client, further demonstrating the exceptional capability of cryogenic deburring technology for handling high-rigidity, high-precision engineering plastic components.

The Challenge: PBT with Glass Fiber Presents Bottleneck for Traditional Deburring

PBT engineering plastic is widely used in automotive, electronic connectors, precision instruments, and other fields due to its excellent electrical properties, heat resistance, and mechanical strength. While the addition of glass fiber (GF) enhances its rigidity and dimensional stability, it also introduces new challenges. This composite material is hard and possesses good toughness, resulting in burrs that are both rigid and fine during the injection molding process. Traditional manual deburring methods are not only inefficient but also highly prone to causing product scratches, exposed fibers, or dimensional deviations, severely impacting product quality and yield rates.

The Solution: Deep Freeze Embrittlement and Precision Removal

Faced with the precision test part provided by the client, our technical team utilized a professional Cryogenic Deburring Machine. The core principle of this technology leverages low-temperature embrittlement. The parts are placed in an ultra-low temperature environment (typically reaching -80°C to -160°C), causing the molecular chains of the burrs to lose mobility and become extremely brittle. Simultaneously, the main body of the part, due to its greater mass and heat capacity, remains relatively ductile.

Subsequently, specific media (like polymer plastic pellets) are projected at high velocity, uniformly impacting the embrittled burrs. The burrs shatter and detach instantly upon impact, while the part itself remains completely undamaged. The entire process is automatic, requires no chemicals, and achieves a perfect combination of high efficiency, environmental friendliness, and superior quality.

Test Results: Exceptional Performance Exceeding Expectations

This test validated the highly satisfactory performance of the Cryogenic Deburring Machine on the PBT+GF injection molded part:

-

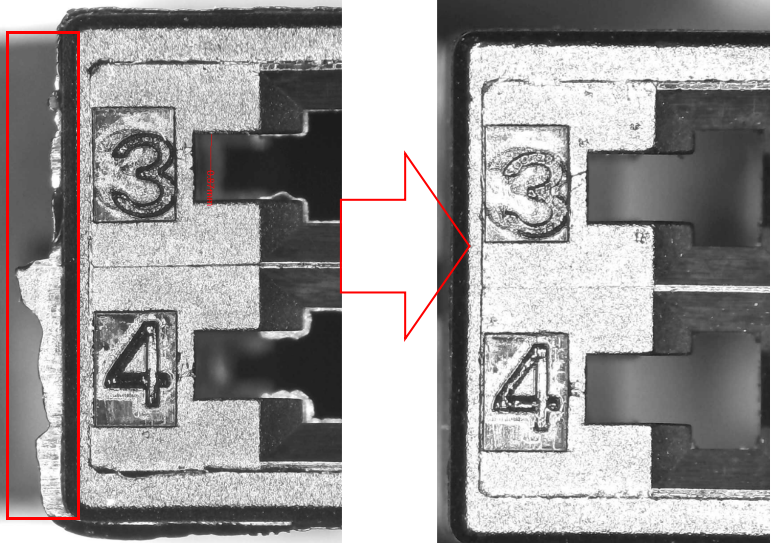

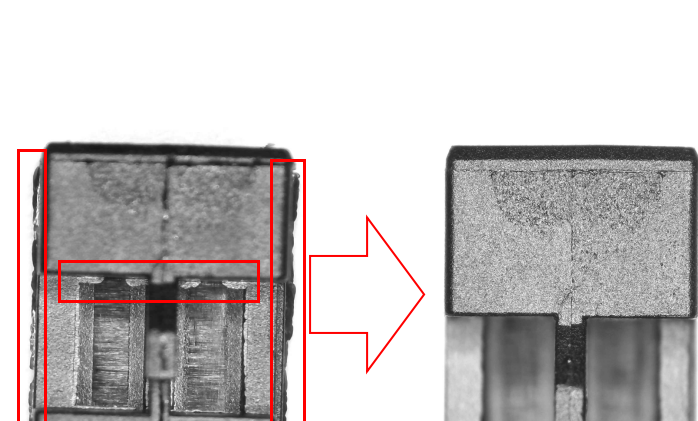

Thoroughly Cleaned: All micron-level burrs and flash were effectively removed from parting lines, hole edges, and within complex geometric structures.

-

Zero Damage: The part itself, particularly the glass fiber structure, sustained no impact damage, perfectly preserving its original dimensional accuracy and mechanical properties.

-

Dramatic Efficiency Gain: A single cycle can process hundreds or even thousands of parts, increasing efficiency more than tenfold compared to manual deburring.

Broader Impact: Injecting New Momentum into Precision Plastic Manufacturing

The success of this test signifies that Cryogenic Deburring Machine technology is ideally suited to solve the deburring challenges of high-end engineering plastic components. It offers a revolutionary solution for manufacturing precision plastic parts such as electronic connectors, automotive sensors, and micro-gears, where impeccable cleanliness and reliability are paramount.

“[Your Company Name] is committed to providing customers with cutting-edge surface treatment solutions,” stated the company’s Technical Director. “The success of this test further solidifies our leading position in deburring technology for precision components. We look forward to extending this mature technology to more industries, helping customers enhance product quality and reduce production costs.”

Post time: Sep-30-2025