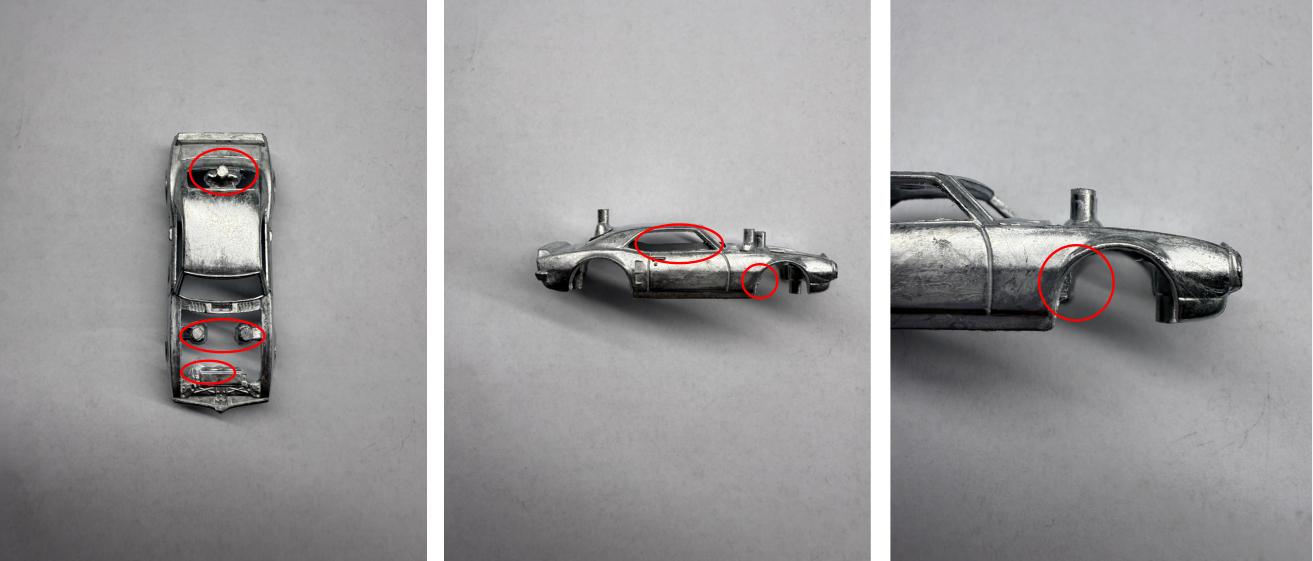

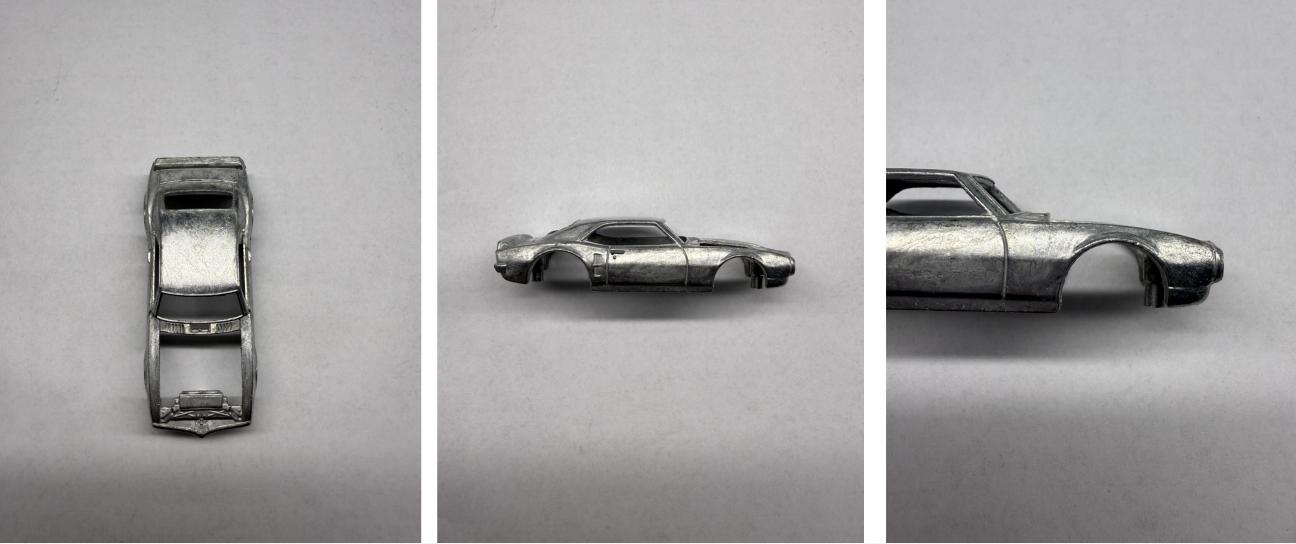

Recently, STMC received a special “test case”—a sample zinc alloy toy car from an overseas client. The challenge was clear: address the problematic flashing, particularly along the parting lines and gate areas. The client’s goal was to find a high-efficiency, non-destructive finishing solution. STMC accepted the challenge and delivered a perfect result: we utilized our self-developed Cryogenic Deflashing Machine, designed specifically for zinc alloys, to provide expert contract processing services.

This was more than just a standard processing job; it was a live demonstration of our equipment’s capabilities. As the manufacturer of the machine, STMC knows that the most powerful testimony is a flawless finished product achieved with our own technology. Leveraging our deep understanding of the machine’s performance, we precisely set the process parameters. The toy car was exposed to ultra-low temperatures (below -80°C), instantly embrittling the flashes, which were then removed by high-speed media bombardment—resulting in a smooth, clean, and perfectly intact product.

The STMC Advantage: Dual Assurance for Your Success

Technology Assurance: The Cryogenic Deflashing Machine we used offers flexible capacity (60-180L) and is specifically engineered for zinc, magnesium, and aluminum die-cast parts, ensuring uniform and highly effective results.

Expertise Assurance: As the original equipment manufacturer (OEM), our processing team possesses unparalleled knowledge of the machine’s potential. We can identify the optimal processing parameters for your specific part, eliminating the guesswork and risk of “trial and error” after purchasing equipment.

Does Your Product Suffer from Flashing Issues?

STMC invites potential clients worldwide to send us their samples for a “manufacturer-level” contract processing experience. Let the results speak for themselves. Whether you are looking to purchase advanced equipment or outsource your deflashing needs, STMC is your reliable partner.

Post time: Sep-26-2025