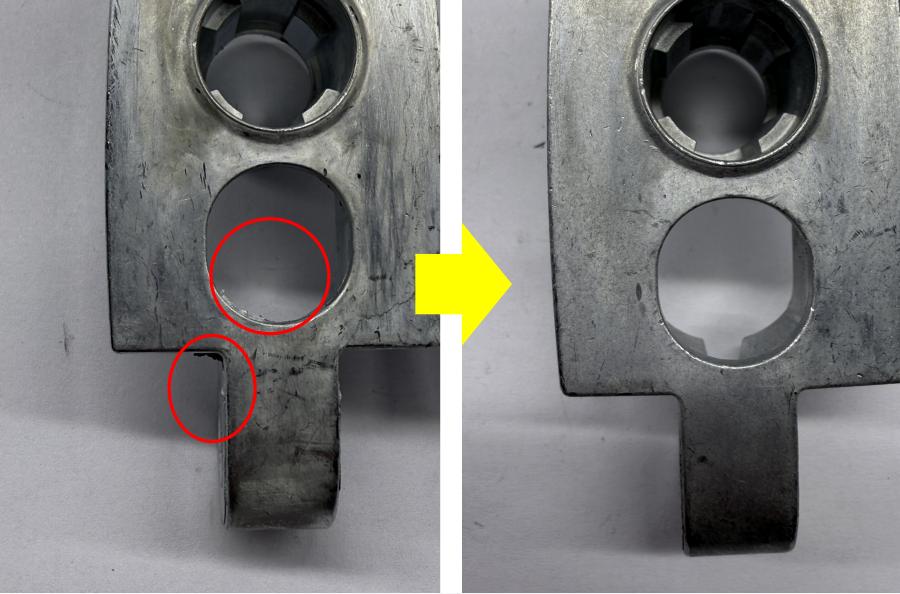

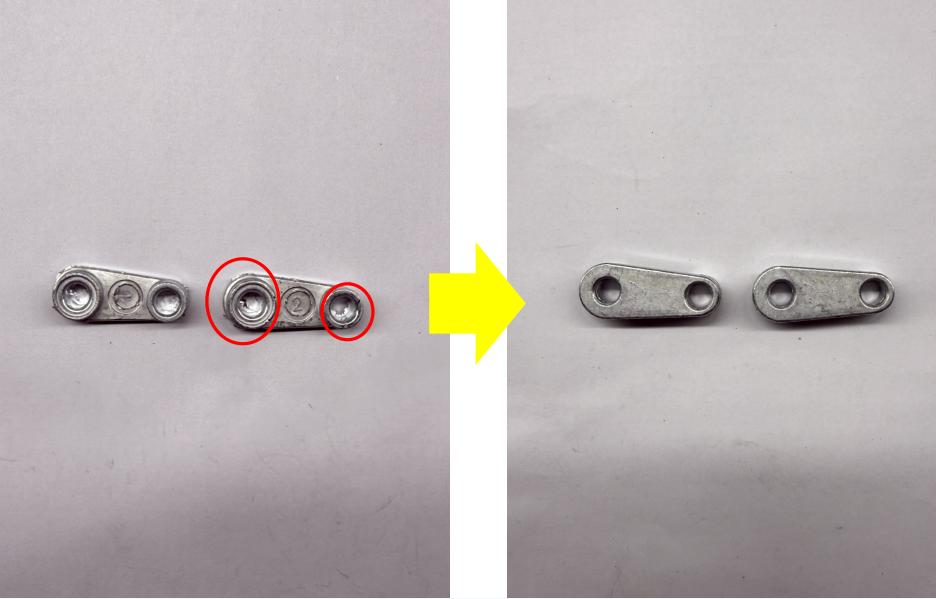

Today, we conducted our standard cryogenic defalshing/deburring test on seven different types of zinc alloy die-cast parts. As a mandatory step before every batch of contract processing or equipment delivery, STMC dedicated zinc alloy cryogenic deflashing/deburring machine once again demonstrated its reliable and efficient performance.

During the test, all flash along the parting lines was completely removed, leaving the workpiece surfaces smooth and edges naturally transitioned—showcasing the ideal synergy between process and equipment. This is exactly the purpose of our ongoing validation: to ensure that every machine and every contract processing service delivers consistently high-quality deburring results for our customers.

This cryogenic deflashing/deburring machine, designed specifically for zinc alloys, remains the core equipment we trust:

-

Equipped with a cyclone exhaust system, it ensures thorough media separation during processing and maintains efficient operation.

-

Featuring SGP high-performance insulation and an SUS304 stainless steel housing, it provides stable low-temperature conditions while ensuring durability and easy maintenance.

-

Beyond deburring, the process also enhances the oxidation resistance of zinc alloy surfaces, contributing to extended workpiece service life.

In terms of safety, the machine continues STMC consistent rigorous design:

-

Comprehensive explosion-proof treatment and a top-mounted pressure relief safety port ensure safe and controlled operation throughout the process.

Each test is like a dialogue with the equipment; each validation is a commitment fulfilled to our customers. STMC will continue to deepen its expertise in cryogenic deburring, providing reliable processes and equipment to support every zinc alloy manufacturing partner.

Post time: Dec-02-2025