In the injection molding industry, the quality of molded parts is crucial. This is especially true for precision molded gears, as their quality directly impacts the performance and stability of the entire mechanical equipment. However, removing internal burrs from these precision gears has long been a challenging problem. Traditional deflashing methods often fail to achieve ideal results, while the emergence of Cryogenic Deflashing Machines offers a new solution. This article will explore the application and advantages of using Cryogenic Deflashing Machines to remove internal burrs from precision molded gears.

The Harm Caused by Internal Burrs in Precision Molded Gears

During the molding process, burrs are inevitably created due to factors like mold precision and injection parameters. These burrs may seem tiny, but they can seriously affect the gear’s performance and lifespan. Firstly, burrs can impair transmission accuracy. During operation, they can cause poor meshing between gears, leading to noise, vibration, and reduced transmission efficiency. Secondly, burrs accelerate wear. When gears operate at high speeds, burrs rub against other components, increasing surface wear and shortening service life. Additionally, burrs can affect assembly quality, causing issues like jamming during assembly, which disrupts the normal operation of the entire machinery.

Limitations of Traditional Deflashing Methods

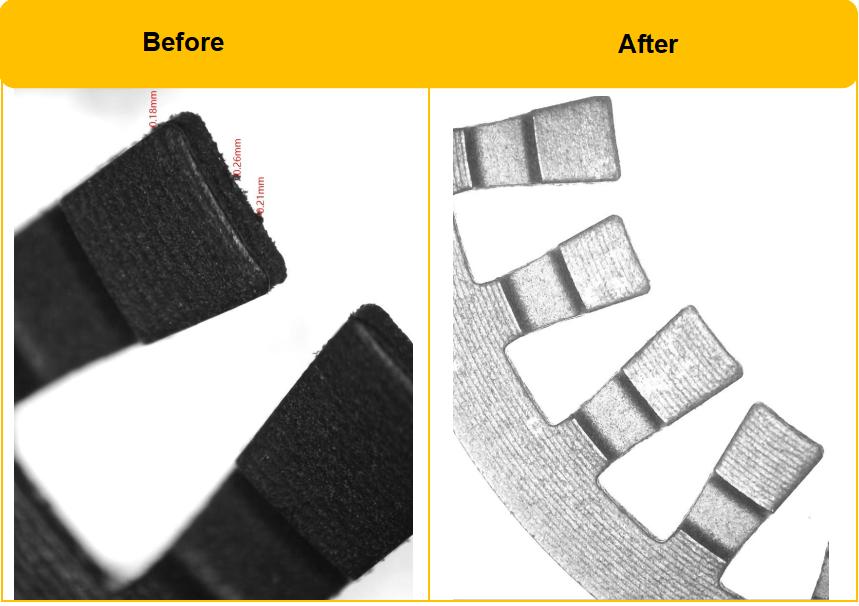

Traditional methods for removing burrs include manual and mechanical deflashing. However, these approaches have significant limitations. Manual deflashing, where operators use tools to remove burrs by hand, offers high flexibility for gears of different shapes and sizes. But it is inefficient, labor-intensive, and the quality varies greatly depending on the operator’s skill and experience. Furthermore, it’s difficult to effectively remove tiny internal burrs manually. Mechanical deflashing uses equipment like grinding wheels or polishers. These machines can improve efficiency but have their own drawbacks. For example, grinding wheels can generate heat, potentially warping the gear, and polishers often struggle to handle minute internal burrs effectively.

How the Cryogenic Deflashing Machine Works

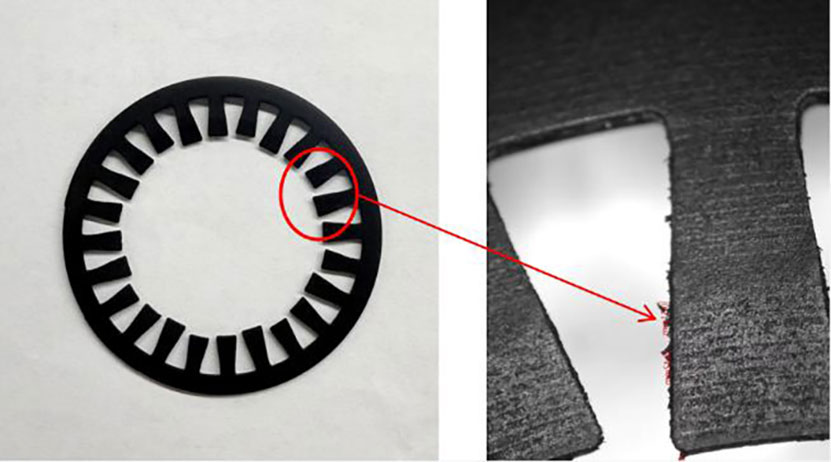

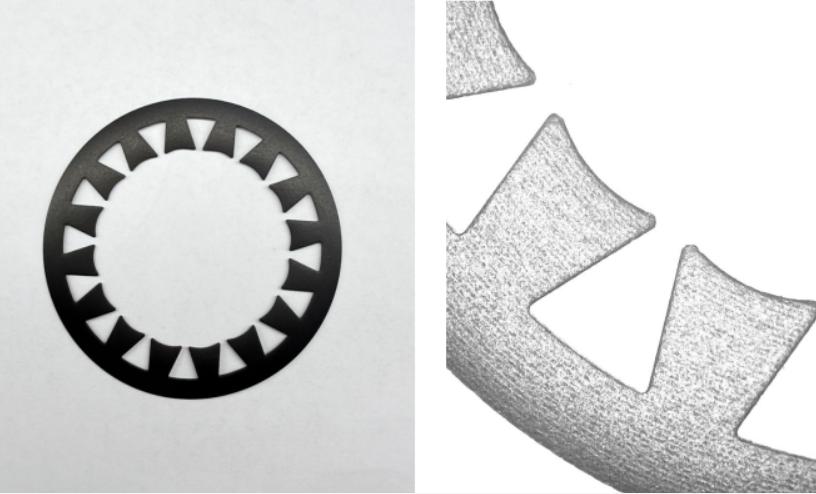

A Cryogenic Deflashing Machine uses liquid nitrogen to rapidly freeze and embrittle the flash or burrs on a part. In this brittle state, high-speed projectiles are blasted at the part. These projectiles impact and break off the now-brittle burrs. Because the burrs are much thinner than the gear itself, they freeze and become brittle much faster. The process occurs in the short window of time after the burrs have embrittled but before the core part does. This unique principle allows the machine to precisely remove burrs without altering the physical properties of the gear itself.

Advantages of Using a Cryogenic Deflashing Machine for Precision Gears

Compared to traditional methods, Cryogenic Deflashing Machines offer significant advantages for removing internal burrs from precision gears:

High Precision: The projectile blasting can accurately target and remove even microscopic internal burrs, meeting strict precision requirements.

High Efficiency: It can process large volumes of gears in a short time, greatly boosting production efficiency.

Low Cost: It uses standard, non-proprietary consumables (like 25mm projectiles), keeping operational costs low.

Uniform Results: It uniformly removes burrs from entire surfaces and effectively handles burrs on external edges, internal holes, and complex shapes—a consistency level difficult to achieve manually or with other machines.

No Damage: The process does not affect the physical properties of the gear, preserving its original performance and integrity.

Application Case Studies

Practical examples demonstrate the effectiveness of Cryogenic Deflashing Machines. One precision molding company struggled with removing internal gear burrs using traditional methods, which were inefficient and yielded poor quality. After installing a Cryogenic Deflashing Machine, they achieved fast and precise burr removal, significantly improving quality and productivity, leading to substantial economic benefits. Another gear manufacturer also reported excellent results, enhancing their product’s market competitiveness and customer satisfaction. These cases confirm the machine’s effectiveness and reliability for this application.

Conclusion

Removing internal burrs from precision molded gears is a critical challenge in the injection molding industry. Traditional methods have limitations, but the Cryogenic Deflashing Machine, with its unique working principle and clear advantages, provides an effective solution. Case studies show it can precisely remove internal burrs, improve deflashing accuracy and production efficiency, and reduce costs. As technology advances, the performance of these machines will continue to improve, leading to wider adoption in the industry. Therefore, investing in a Cryogenic Deflashing Machine is a crucial step for injection molding companies to enhance product quality and strengthen their market competitiveness.

Post time: Sep-19-2025