In modern manufacturing, removing burrs from materials such as plastics and rubbers has always been a key factor affecting the appearance and quality of products. Traditional deburring methods, such as manual trimming or mechanical grinding, are not only inefficient but also may damage the surface of the products. The emergence of the Cryogenic Deflashing Machine provides an efficient and precise solution to this problem.

The Working Principle of the Cryogenic Deflashing Machine

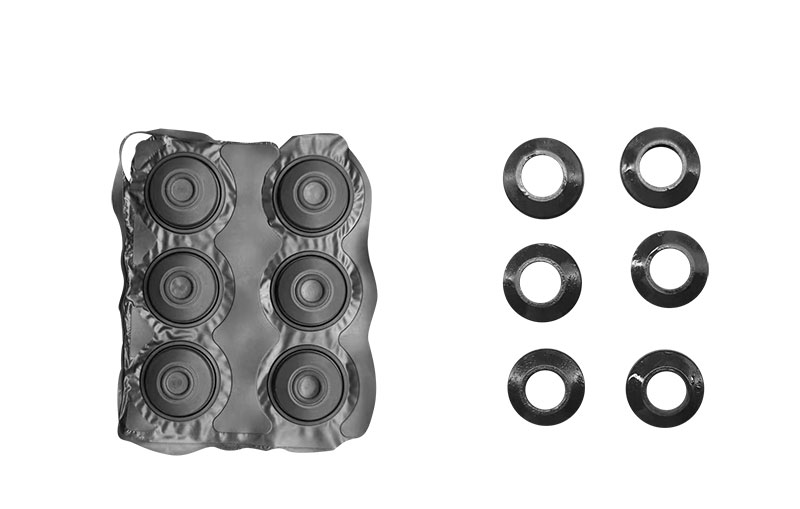

The Cryogenic Deflashing Machine utilizes low-temperature freezing technology to rapidly embrittle the burrs of the products, and then impacts the burrs with high-speed injected media (shot) to make them fall off. The entire process does not require manual intervention, avoiding the potential scratching or deformation problems that may occur in traditional methods, especially suitable for precision parts with complex shapes.

Why is the Cryogenic Deflashing Machine More Efficient?

1. Automated operation saves labor: The equipment can process workpieces in batches, significantly reducing the time cost of manual deburring.

2. Deburring without damage: The low-temperature embrittlement technology ensures that the main body of the product is not affected by the impact and maintains dimensional accuracy.

3. Wide applicability: It is suitable for various materials such as rubber, silica gel, zinc alloy, and plastic, and is particularly suitable for industries such as precision electronic components and automotive parts.

4. Environmentally friendly and energy-saving: Compared with chemical deburring methods, cryogenic deflashing is pollution-free, and the media can be recycled.

Industry Application Cases

After a certain automotive parts manufacturer adopted the Cryogenic Deflashing Machine, the deburring efficiency increased by 80%, and the product defect rate decreased significantly. At the same time, due to the reduction of manual operation, the production cost was effectively controlled, and customer satisfaction was greatly improved.

Future Development Trends

With the advancement of Industry 4.0, intelligent Cryogenic Deflashing Machines are gradually integrating functions such as automatic feeding and AI quality inspection, further promoting the development of the manufacturing industry towards high efficiency and high precision.

The Cryogenic Deflashing Machine, with its unique advantages, is becoming the preferred equipment for deburring in modern factories. By introducing this technology, enterprises can not only enhance the competitiveness of their products but also achieve cost reduction and efficiency improvement, contributing to industrial upgrading.

Post time: May-09-2025