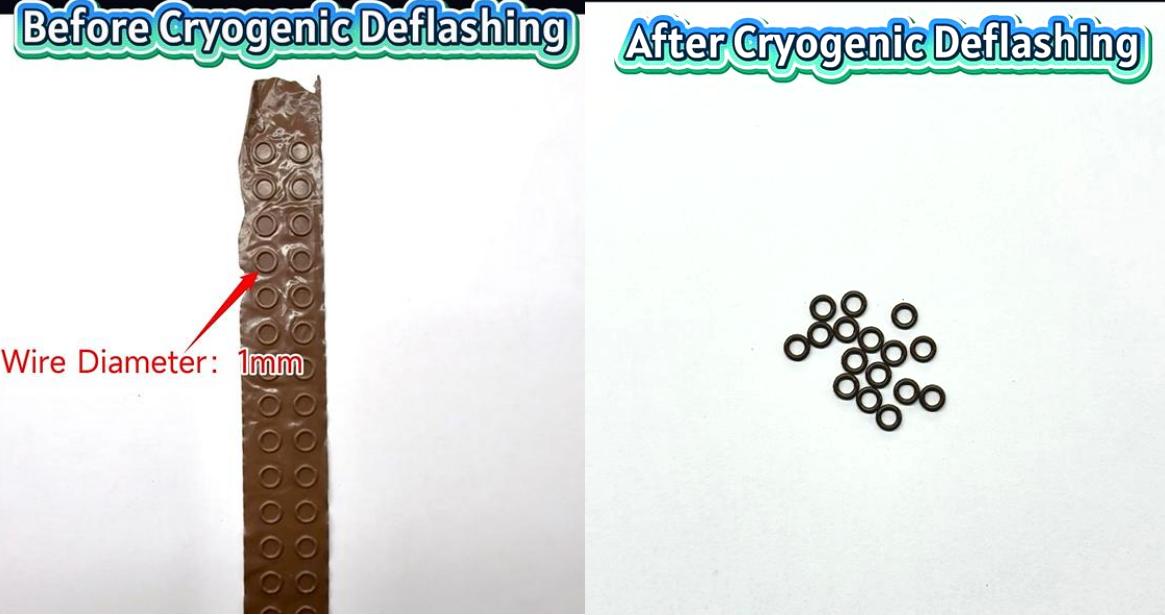

Recently, STMC in Nanjing undertook a batch of fluorocarbon rubber (FKM) O-rings with a cross-sectional diameter of only 1mm, produced by a client, and provided cryogenic deflashing processing services.

Challenges and Opportunities Coexist: The Pursuit of Precision in Delicate Parts

Fluorocarbon rubber (FKM) is widely used in high-end industries such as automotive, aerospace, and petrochemicals due to its exceptional resistance to high temperatures, oils, and chemical media. However, removing the tiny flashes (burrs) generated after molding O-rings with cross-sectional diameters as fine as 1mm has long been a technical challenge in the industry. Traditional manual or mechanical deflashing methods are prone to damaging the product body, compromising sealing performance and dimensional accuracy, while also being inefficient. Driven by the pursuit of “zero-defect” quality, the client entrusted this critical process to STMC, relying on its core equipment and technical expertise.

Independent Innovation: The Ultra Shot Cryogenic Deflashing Machines

As a leading enterprise in China’s cryogenic deflashing machine sector, specializing in design, R&D, and manufacturing, STMC remains committed to independent innovation. The company’s flagship product, the NS Series Cryogenic Deflashing Machine, represents years of dedicated research and development. Renowned for its high precision, efficiency, and reliability, it fills multiple technological gaps in the domestic market and has successfully served numerous clients in the rubber, plastics, and precision casting industries.

Professional Equipment, Refined Craftsmanship: The NS-120 Series Takes on the Challenge

To successfully complete this high-difficulty deflashing task for FKM O-rings, STMC deployed its star model—the NS-120 Cryogenic Deflashing Machine. With its outstanding performance features, this machine is the ideal choice for processing such small, precision rubber components:

High Deflashing Precision: Utilizing advanced deep-freezing and flexible jetting technology, it accurately removes micron-level flashes while perfectly protecting the product structure and dimensions, ensuring the O-rings meet all sealing performance requirements.

Large Processing Capacity, Exceptional Efficiency: Its automated batch-processing capability significantly enhances deflashing efficiency, shortens the delivery cycle for client products, and helps clients reduce costs while improving productivity.

Broad Process Adaptability: Particularly suitable for various small and medium-sized, structurally complex rubber parts (such as O-rings, oil seals, diaphragms, etc.) and precision injection-molded components, addressing deflashing challenges that traditional methods cannot handle.

The smooth execution of this processing project serves as another vivid demonstration of the exceptional performance of STMC’s NS Series equipment. Through meticulous process parameter adjustments and comprehensive quality control, STMC’s technical team ensured that every 1mm cross-sectional diameter FKM O-ring achieved the flawless quality expected by the client.

Post time: Jan-06-2026