Nitrile rubber (NBR) is widely used in precision sealing components for automotive, medical, and electronics industries due to its excellent oil resistance, wear resistance, and elasticity. However, under 60x electron microscopy, micro-flash at the parting line remains a persistent issue. Traditional manual or mechanical trimming methods risk product damage and suffer from low efficiency, failing to meet high-precision requirements.

NS-60 Cryogenic Deflashing Machine

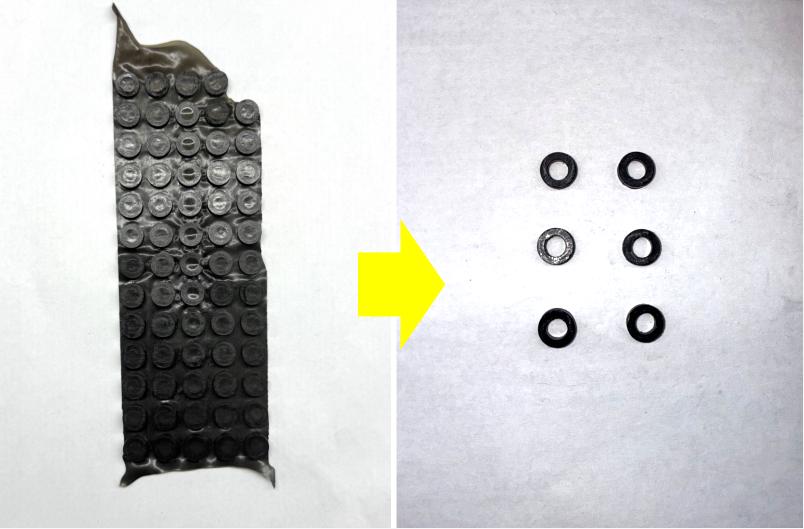

To address this challenge, our technical team has optimized cryogenic deflashing technology using theNS-60 Cryogenic Deflashing Machine, paired with custom micro-perforated part baskets to prevent small components from being lost during processing. By precisely controlling freezing temperature, media flow rate, and deflashing duration, flash is efficiently removed, significantly improving surface smoothness to meet high-magnification inspection standards.

Key Advantages:

✔ High-Precision Trimming – Complete flash removal at the parting line with no residue, compliant with 60x microscope inspection.

✔ Zero Damage – Low-temperature embrittlement technology avoids mechanical stress, preserving structural integrity.

✔ Enhanced Efficiency– Automated process increases productivity by 50%, ideal for mass production.

✔ Custom Solutions – Adjustable basket apertures and processing parameters to fit different product sizes.

About Us

As a leader in precision rubber processing, we drive industry advancement through innovation. For more details on cryogenic deflashing or collaboration opportunities, visit our website or contact our technical team.

Post time: Aug-19-2025