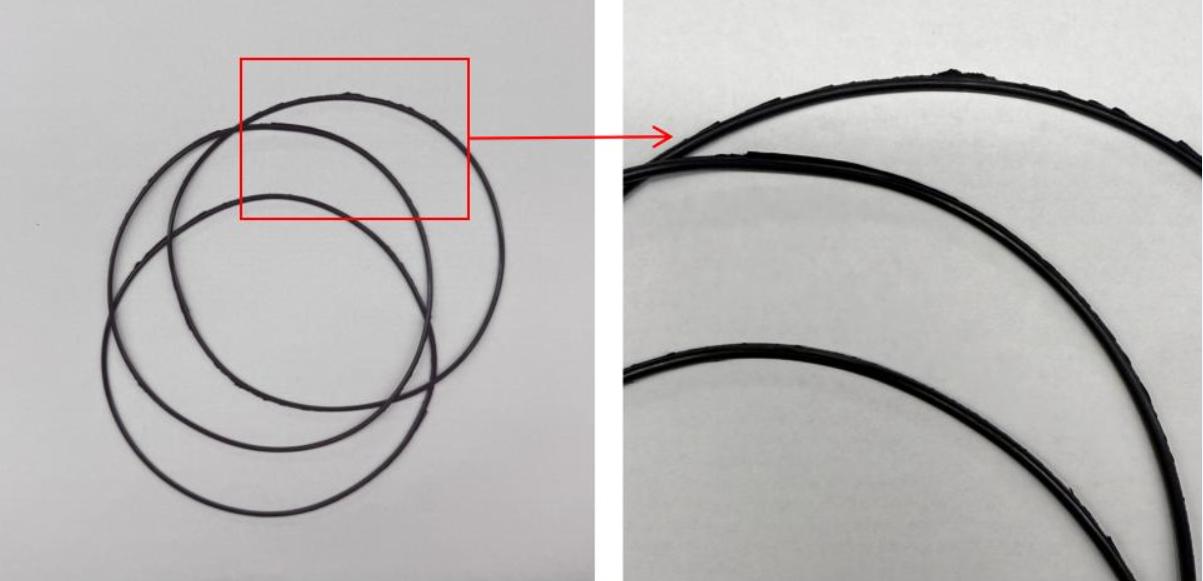

A customer manufacturing nitrile rubber rings encountered persistent, fine residual flashing along the parting lines after initial trimming with a spinning machine. This issue not only affected product appearance and dimensional accuracy but also posed potential risks to subsequent assembly and performance. To address this challenge, the customer ultimately chose Nanjing STMC, a company with extensive experience and a strong reputation in the field of cryogenic deflashing.

After thoroughly analyzing the product characteristics, STMC’s technical team employed the NS-120 Cryogenic Deflashing Machine. This model is a mature product designed by STMC specifically for deburring needs of rubber, engineering plastics, and precision injection-molded parts. It is characterized by high efficiency, environmental friendliness, and non-damaging operation, making it widely suitable for flash removal on workpieces with comple structures.

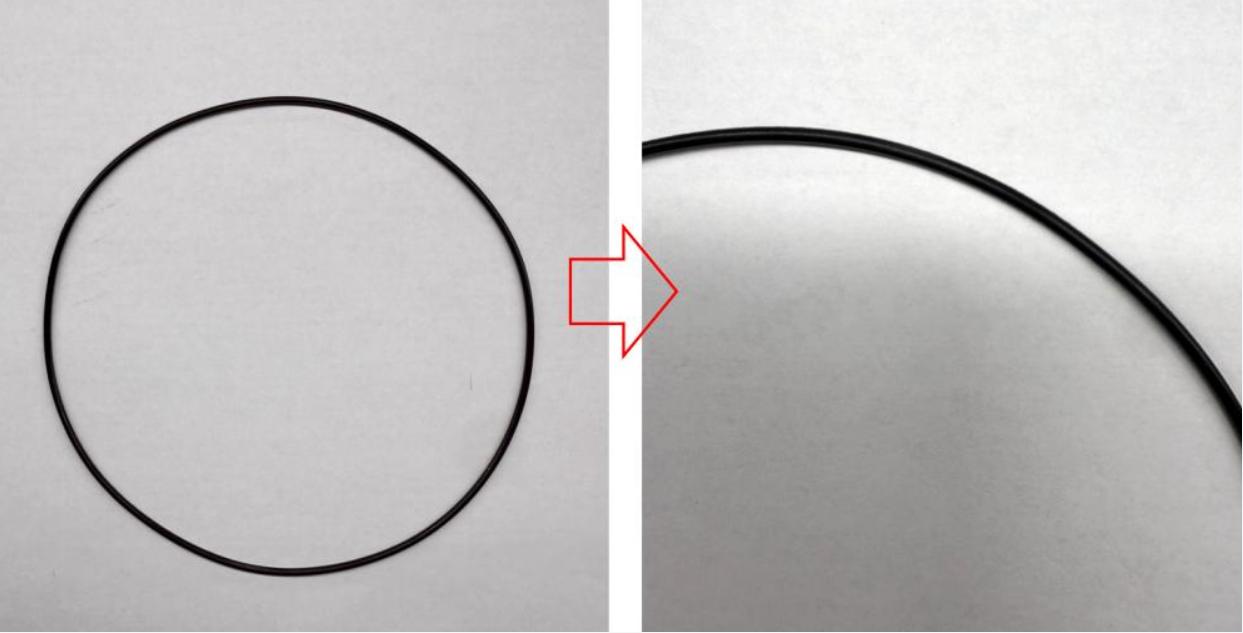

During the actual process, the NS-120 demonstrated outstanding performance. Utilizing the principle of extreme low-temperature embrittlement combined with high-speed projectile blasting, the machine was able to precisely and completely remove all residual flashing from the nitrile rubber rings’ parting lines within a single-cycle processing time of approximately ten minutes. After treatment, the product surface was smooth and even, with no damage, deformation, or alteration to material properties, fully meeting the customer’s stringent requirements for high-quality appearance and dimensional tolerances.

This successful application not only resolved the customer’s production challenge but also further validated the unique advantages of Nanjing STMC’s cryogenic deflashing technology for handling highly elastic and soft rubber components. With its stable processing results, fast cycle times, and flexible adaptability, the NS-120 has become a reliable choice for numerous partners in the rubber and injection molding industries seeking to enhance product quality and optimize production processes.

Nanjing STMC is committed to providing advanced surface treatment and deburring solutions for the manufacturing industry. Our professional technical team can offer customized process testing and equipment selection support based on different industries, materials, and product structures. Whether you are facing similar deflashing challenges or looking to improve your existing processes, we welcome you to contact us.

Choose STMC—choose precision and reliability!

Post time: Dec-17-2025