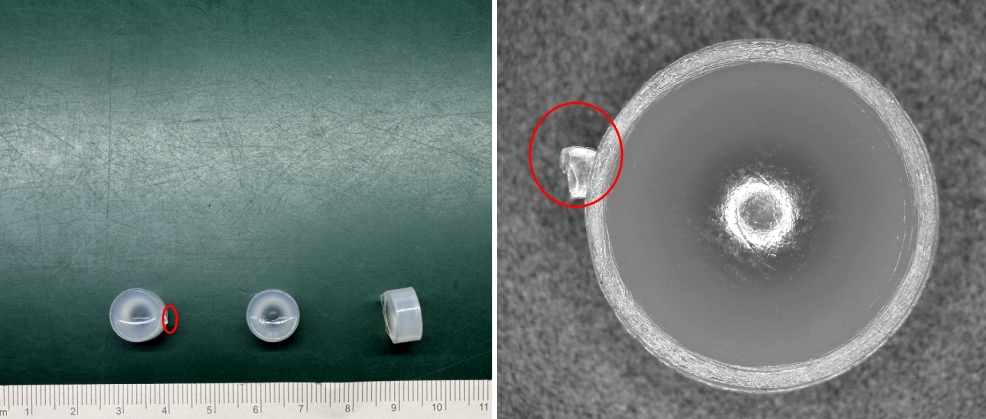

In the field of precision injection molding, burr removal for micro-sized workpieces has long been an industry pain point. Take nylon injection-molded parts with diameters as small as 1cm, for example—their edge burrs are difficult to handle due to the part’s tiny size and intricate structure. Traditional manual deburring is inefficient and risks damaging the workpiece. To address this challenge, the NS-60C Cryogenic Deflashing Machine has emerged as an ideal alternative, leveraging high-precision, non-contact cryogenic deflashing technology to provide an efficient and damage-free solution for rubber and precision plastic components.

The Challenge of Micro Workpiece Deflashing: Manual Limitations vs. Cryogenic Advantages

After injection molding, nylon parts often retain fine burrs along their edges. However, their small size (around 1cm) makes deburring even more challenging: manual operations require magnification tools, are time-consuming, and lack consistency, while mechanical grinding may cause deformation or dimensional inaccuracies.

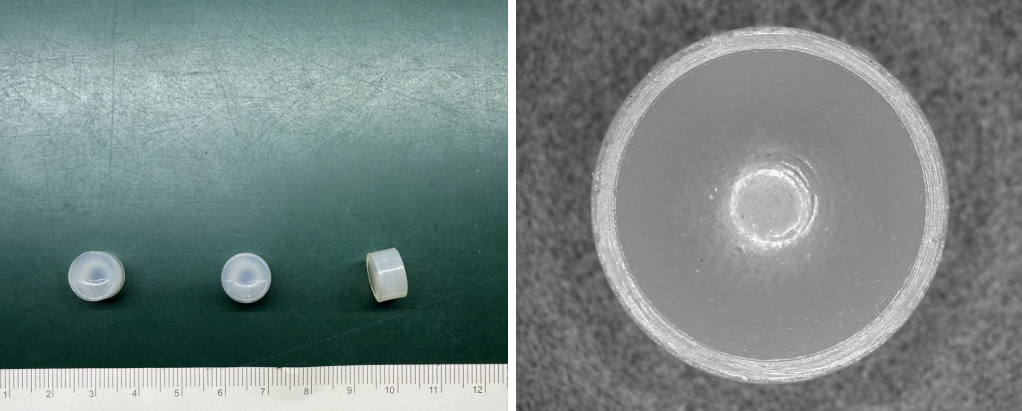

The NS-60C Cryogenic Deflashing Machine utilizes a -60°C freezing process combined with high-speed polymer media blasting to instantly remove burrs without contacting the workpiece surface. This method is particularly suitable for batch processing of micro-sized molded parts, achieving a deflashing precision of ±0.01mm while preserving structural integrity, improving yield rates to over 99%.

Core Advantages of the NS-60 Series: Engineered for Precision Components

High-Precision Deflashing

Equipped with an intelligent control system, it automatically adjusts temperature and blasting parameters for materials like nylon and rubber, ensuring complete burr removal without surface damage.

Wide Compatibility

Suitable for precision molded parts (1cm–10cm), rubber seals, medical tubing, and more—especially effective for complex geometries with hard-to-reach burrs.

High Efficiency & Energy Savings

Each cycle takes only 5–15 minutes, supporting batch processing with 20x higher efficiency than manual labor and 40% lower energy consumption compared to conventional deflashing equipment.

Eco-Friendly & Safe

Fully enclosed operation eliminates dust pollution, complying with ISO 9000 environmental standards for a cleaner workspace.

Industry Application Case

An automotive parts supplier adopted the NS-60C for deburring nylon gears (1.2cm diameter). Previously, manual deflashing took 2 minutes per piece; with cryogenic deflashing, they achieved 200 pieces/15mins in full automation, reducing costs by 150%.

Future Outlook

As demand for micro-sized precision components grows in industries like 5G electronics and medical devices, cryogenic deflashing is becoming a standard solution. The NS-60 series continues to advance with smart upgrades, delivering even higher efficiency for next-gen manufacturing.

Post time: Jun-19-2025