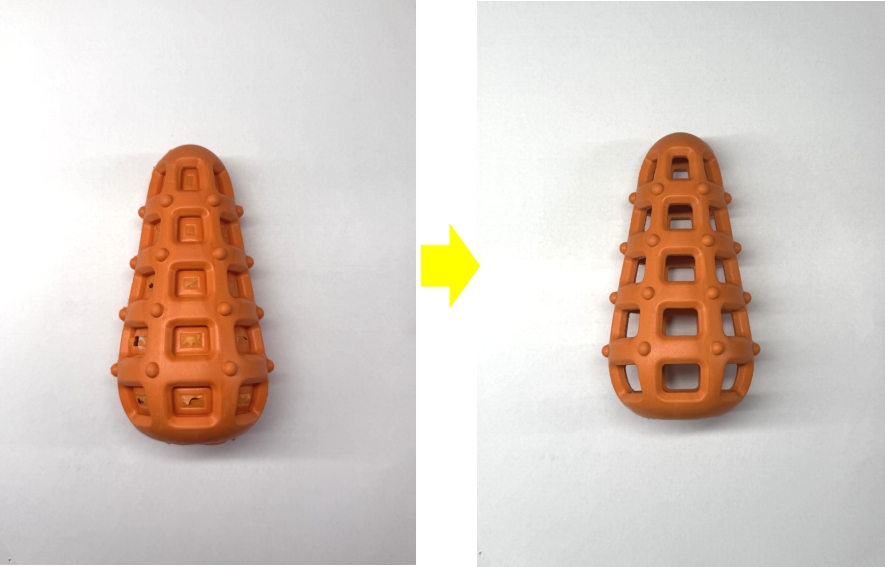

Recently, STMC provided cryogenic deflashing and processing services for a pet toy manufacturer, successfully treating a batch of 200kg rubber pet toys. The product, made of natural rubber, features an internal design that allows for snack filling, with treats slowly released through small holes to enhance interactive play for dogs. However, newly manufactured toys faced issues with overflow rubber clogging the holes. Traditional manual deflashing proved inefficient, while mechanical trimming resulted in residual flashes and inadequate cleanliness, significantly impacting delivery quality.

Industry Pain Points

Low efficiency of traditional deflashing methods: Manual deflashing is time-consuming, labor-intensive, and costly.

Poor results from mechanical deflashing : Trimming machines often leave behind residual flashes and fail to ensure hole cleanliness.

High-quality requirements: Pet toys must meet food-grade safety standards, demanding superior surface smoothness.

STMC’s Innovative Cryogenic Deflashing Solution

To address these challenges, STMC employed a professional cryogenic deflashing machine (NS-160T) combined with deep-freeze deflashing technology, achieving efficient and precise flash removal:

✅ Effective overflow rubber removal: Ultra-low-temperature freezing technology embrittles rubber flashes, which are then removed via high-speed media blasting, ensuring unobstructed holes.

✅ High-precision processing: Prevents potential product damage from manual or mechanical deflashing , maintaining the toy’s structural integrity.

✅ Clean and residue-free: The cryogenic deflashing process is chemical-free, complying with pet product safety standards.

✅ High-volume processing capacity: A single batch handles 200kg of products, significantly boosting production efficiency.

Customer Benefits

✔ 100% flash removal rate, restoring hole functionality to ensure smooth snack dispensing.

✔ Over 30% cost savings, with a 5x efficiency increase compared to manual deflashing.

✔ Upgraded product quality, featuring smooth, burr-free surfaces to enhance market competitiveness.

STMC specializes in cryogenic deflashing and flash removal technologies, providing efficient post-processing solutions for rubber, silicone, and plastic products. We help businesses reduce costs, improve efficiency, and overcome production bottlenecks.

Post time: Jul-03-2025