STMC brings two decades of dedicated expertise in cryogenic deflashing technology, integrating R&D, manufacturing, and sales to offer complete solutions, including professional deflashing services.

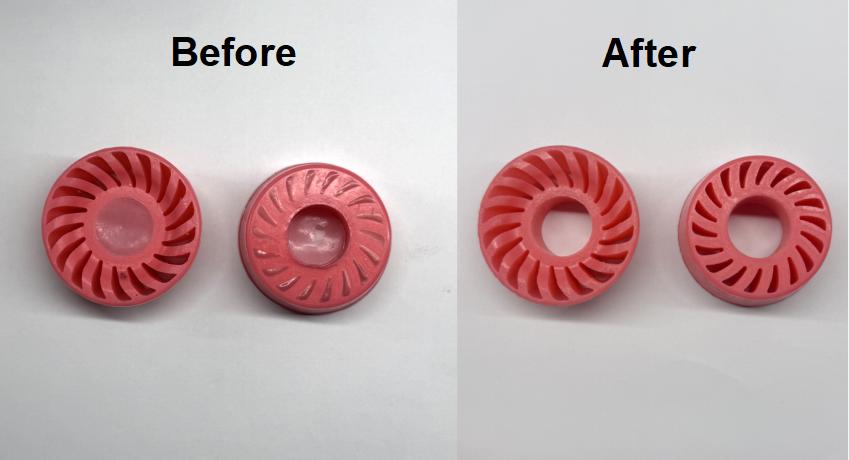

A recent application involved deflashing a batch of polyurethane sun gears for a customer. The primary challenge was the extensive residual internal flashing within the part’s intricate holes, which is difficult to remove with conventional methods.

Utilizing STMC’s advanced Cryogenic Deflashing Machine, the internal burrs were efficiently and completely removed. The process works by embrittting the flash at low temperatures and then removing it with media blasting. This method is particularly effective for complex geometries, ensuring thorough cleaning without any damage to the delicate polyurethane material or critical tolerances.

This successful case highlights the key advantages of STMC’s approach: superior effectiveness for internal features, protection of product integrity, and enhanced processing efficiency. These benefits translate directly into higher quality finishes and reduced overall production costs for our clients.

STMC remains committed to pushing the boundaries of deflashing technology, providing reliable and efficient solutions—from equipment to custom processing services—to help customers achieve manufacturing excellence.

Post time: Oct-16-2025