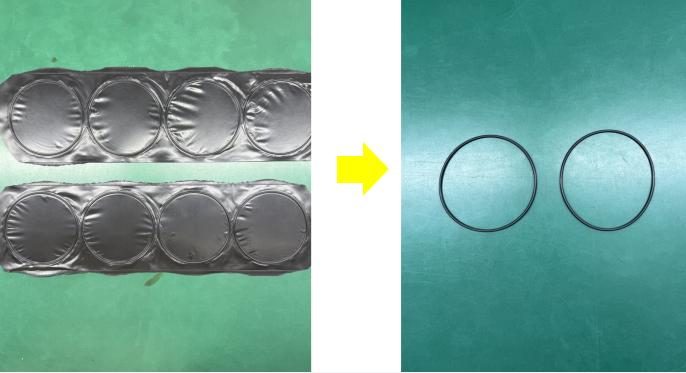

Recently, STMC undertook a cryogenic deflashing order for a client’s ethylene propylene diene monomer (EPDM) rubber rings. The client delivered a large batch of rubber ring products, requiring efficient removal of flash and burrs without damaging the surface, ensuring smoothness and dimensional accuracy. Leveraging advanced cryogenic deflashing technology and extensive processing experience, STMC successfully completed the delivery, earning high praise from the client.

Stringent Process Requirements

EPDM rubber is widely used in automotive, electronics, and construction industries due to its excellent weather resistance, anti-aging properties, and sealing performance. However, traditional manual or mechanical deburring methods can easily cause deformation or surface scratches on EPDM rubber rings, affecting product yield. The client’s shipment consisted of a large quantity of uniformly sized rubber rings, requiring efficient flash removal while ensuring zero damage.

Solution: Ultra-Low Temperature Cryogenic Deflashing Technology

STMC employed industry-leading cryogenic deflashing technology, completing the task with precision through the following steps:

Scientific Batching: Strict weighing and classification of incoming materials to ensure balanced processing per batch.

Multi-Machine Coordination: Simultaneous operation of multiple ultra-low-temperature cryogenic deflashing machines to significantly improve efficiency.

Parameter Optimization: Adjusted temperature, vibration frequency, and duration based on EPDM material properties to ensure flash embrittlement and removal while maintaining the rubber rings’ elasticity and smoothness.

Full Inspection: Post-processing dimensional and surface checks to ensure 100% compliance with client standards.

Key Technical Advantages

Damage-Free: Ultra-low temperatures embrittle flash, avoiding scratches or deformation from mechanical contact.

High Efficiency: Parallel processing with multiple machines, achieving a daily capacity of XX million pieces, shortening lead times.

Eco-Friendly & Safe: No dust or chemical pollution, aligning with green manufacturing standards.

Client Feedback

“STMC’s cryogenic deflashing technology addressed our EPDM product deburring challenges. The processed rubber rings have flawless sealing surfaces, and the delivery was completed 20% ahead of schedule.”

— Client Project Manager

About STMC STMC

specializes in precision cryogenic deflashing services for rubber and plastic components, serving industries such as automotive parts, medical devices, and electronic seals. Equipped with -120°C cryogenic deflashing systems and standardized processes, STMC provides end-to-end solutions from prototype testing → batch processing → quality reporting.

Contact Us For more information on cryogenic deflashing services, visit our website or call: +86-25-5853-5116~5119

Post time: Jun-06-2025