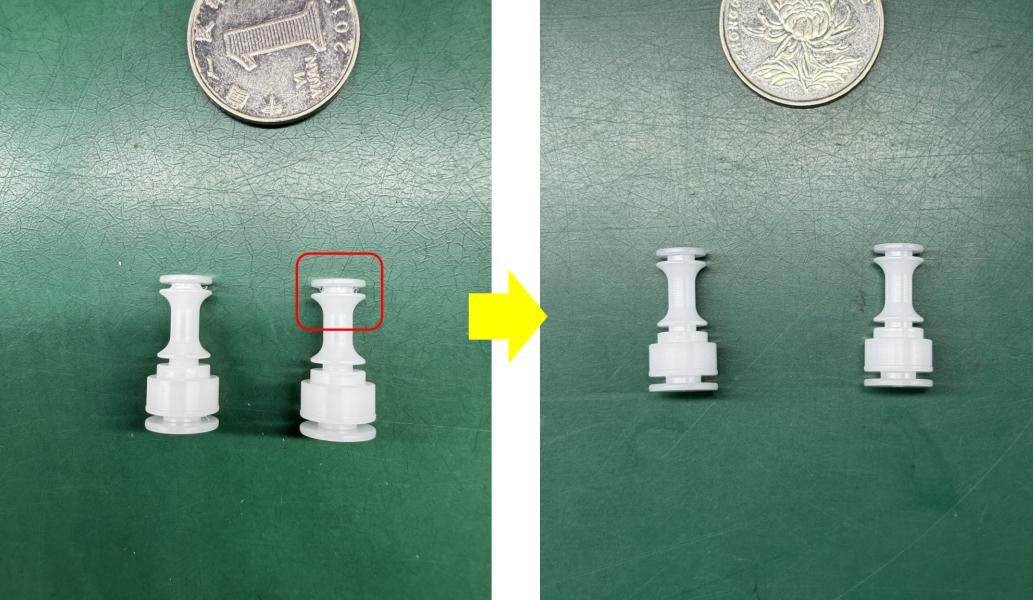

Recently,STMC successfully addressed a customer’s precision deflashing requirements for POM material valve pins using the advanced NS-60T Cryogenic Deflashing Machine. The product, characterized by its small size and intricate structure, had burrs primarily hidden in narrow gaps, making traditional manual deburring prone to omissions and inefficiency. With cryogenic deflashing technology, the process took only 10 minutes, achieving flawless burr removal with no surface residue, significantly improving yield and saving the customer time and costs.

Technical Highlights: The Superior Performance of the NS-60T Cryogenic Deflashing Machine

The NS-60T Cryogenic Deflashing Machine used in this project is an advanced device designed for high-precision, small-batch production of diverse products, offering the following advantages:

Ultra-Low-Temperature Precision Deflashing: Minimum processing temperature down to -130℃, rapidly embrittling burrs for damage-free removal;

High-Efficiency Projection System: Equipped with a **φ250mm aluminum alloy projection wheel**, ensuring uniform force and thorough burr removal in complex structural gaps;

Smart Control: Optional7-inch touchscreen for flexible parameter adjustments, adaptable to workpieces of different materials and shapes;

Large Capacity Processing: 60-liter working volume, balancing efficiency and flexibility, ideal for small-to-medium batch precision part processing.

Application Results: Fast, Clean, and Zero Damage

In this valve pin deflashing case, cryogenic deflashing technology demonstrated significant advantages:

1. Complete Burr Removal: Micron-level burrs embrittle and detach at ultra-low temperatures, eliminating the risk of missed spots in manual deburring;

2. Zero Surface Damage: No scratches or residue on the product, maintaining the original dimensional accuracy of the injection-molded part;

3. Cost Optimization: Short single-piece processing time reduces labor costs by 80%, making it suitable for large-volume orders.

STMC has years of expertise in precision deflashing, specializing in cryogenic deflashing services for engineering plastics such as POM, nylon, and rubber. Moving forward, we will continue to advance our technology to enhance manufacturing quality and efficiency!

Inquiries Welcome for Cryogenic Deflashing Solutions!

Post time: Apr-30-2025