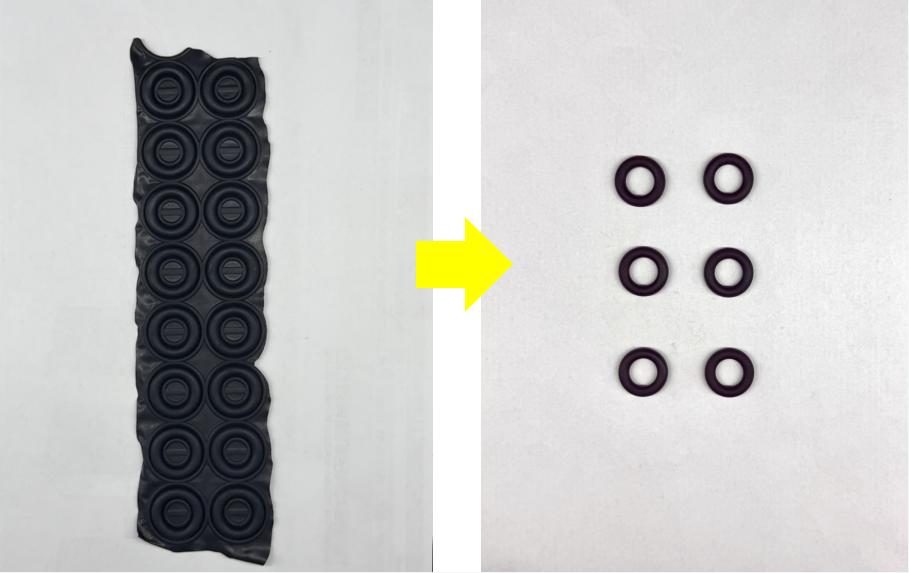

Recently, STMC efficiently completed a cryogenic deflashing/deburring project for a batch of high-precision Ethylene Propylene Diene Monomer (EPDM) O-rings. The client had stringent requirements for surface smoothness and dimensional accuracy, which conventional trimming methods struggled to meet due to residual burrs and low efficiency. Leveraging advanced cryogenic deburring technology and extensive processing experience, STMC deployed dual-machine parallel processing to ensure the high-precision trimming of 800kg of products, enabling on-time delivery and significantly reducing lead time.

Technical Advantage: Cryogenic Deburring Ensures High Precision & Flawless Finish

EPDM O-rings are widely used in automotive and sealing applications, where surface quality and sealing performance are critical. Traditional manual or mechanical trimming often results in burrs and deformation, whereas STMC’s cryogenic deburring technology freezes excess material at ultra-low temperatures, allowing precise removal via high-speed media blasting. This ensures smooth, burr-free edges and full compliance with client specifications.

Efficient Production, Guaranteed Delivery

To meet the client’s urgent demand, STMC optimized production by operating two specialized cryogenic deburring machines simultaneously. The 800kg order was completed on schedule, addressing the inefficiencies and inconsistency of traditional deburring methods while delivering superior quality. The client highly commended STMC’s performance.

STMC remains committed to providing professional and efficient post-processing solutions for rubber products, including cryogenic deburring, flash removal, and surface finishing. Moving forward, we will continue to refine our technologies to help clients enhance product quality and market competitiveness.

For cryogenic deburring services, contact STMC today!

Post time: Aug-12-2025