Recently, STMC successfully tackled the batch deflashing challenge for polyurethane precision parts in the medical industry with its self-developed US-60 Cryogenic Deflashing Machine. While ensuring zero damage to product surfaces, the solution significantly improved production efficiency and product quality, offering a new approach for the medical manufacturing field.

Polyurethane material is widely used in medical devices due to its excellent elasticity and biocompatibility. However, polyurethane products often develop fine burrs after injection molding. Traditional manual deflashing is inefficient and prone to damaging product surfaces, while conventional mechanical methods struggle to meet the strict cleanliness and precision requirements of medical products. Facing this industry pain point, STMC leveraged its over two decades of deep expertise in cryogenic deflashing technology to provide a fully automated deflashing solution tailored to the customer’s needs, based on the US-60 Cryogenic Deflashing Machine.

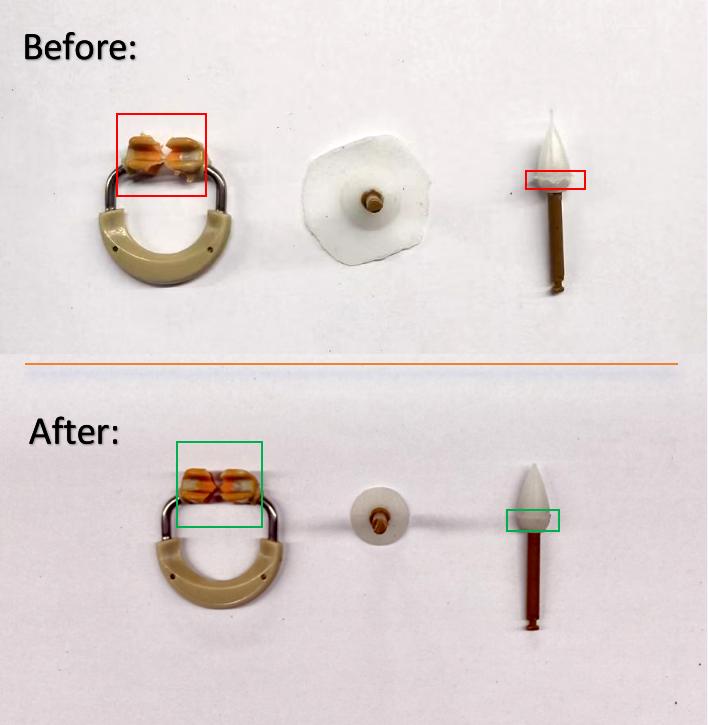

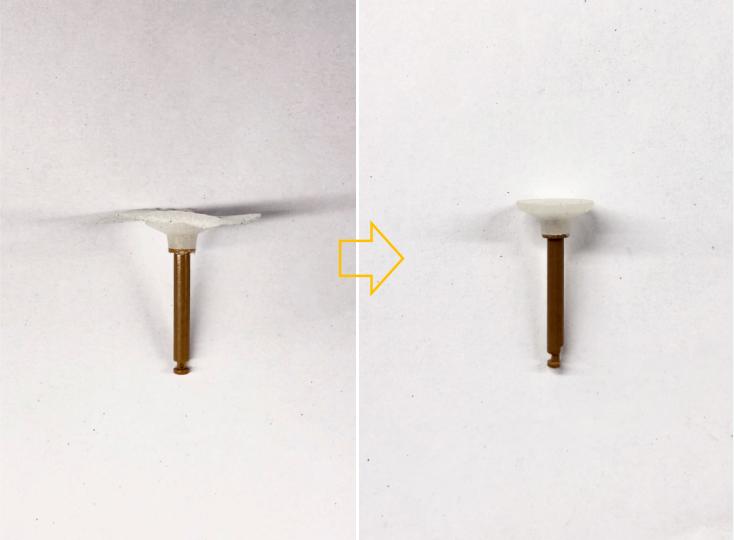

The US-60 Cryogenic Deflashing Machine utilizes an advanced low-temperature jet principle. Liquid nitrogen instantly freezes the burrs on the product surface, making them brittle and easy to remove. The entire process is non-contact, completely avoiding scratches or deformation of the product body. The machine is not only suitable for polyurethane precision parts with complex structures but also enables large-volume continuous operation, improving deflashing efficiency by over 80% while ensuring product dimensional stability and cleanliness fully comply with medical-grade standards.

“Quality and safety in medical products allow no compromise,” stated the Technical Director of STMC. “Our cryogenic deflashing technology uses a non-contact process to remove burrs while protecting product integrity, making it particularly suitable for high-value, high-demand medical component production.” Currently, this solution has been successfully applied to several polyurethane medical products, with customers reporting significant deflashing results, a substantial reduction in defect rates, and fully unleashed production capacity.

As a pioneer in cryogenic deflashing technology in China, STMC has been dedicated to the research, development, and industrialization of this technology since its establishment. Its products now serve multiple high-end manufacturing sectors, including automotive, electronics, and medical. Moving forward, the company will continue to focus on technological innovation, providing customers with more efficient and precise cryogenic deflashing solutions to support the ongoing advancement of Chinese manufacturing toward higher quality and precision.

About STMC

STMC is a high-tech enterprise with over 20 years of expertise in the research, development, and application of cryogenic deflashing technology. It is committed to providing global customers with efficient and precise automated deflashing solutions. The company’s products are widely used in the post-processing of precision rubber, plastic, magnesium alloy, zinc alloy, and other materials, and are renowned in the industry for technological leadership and professional service.

Post time: Feb-09-2026