As a leading innovator in cryogenic deflashing technology, STMC introduces its latest product, the UC-600 Multi-functional Cleaning and Drying Machine. Designed to enhance precision manufacturing post-processing workflows, the UC-600 effectively removes media residues and contaminants from workpiece surfaces after cryogenic deflashing, offering customers an integrated, efficient solution that bridges deflashing with cleaning and drying in a single streamlined process.

The core design philosophy of the UC-600 centers on process integration and operational simplicity. By combining cleaning, dehydration, and drying into one unified system, workpieces can proceed directly from deflashing to full post-treatment within the same machine, eliminating the need for transfer between separate stations. This not only enhances workflow continuity and efficiency but also reduces potential quality risks associated with multiple handlings.

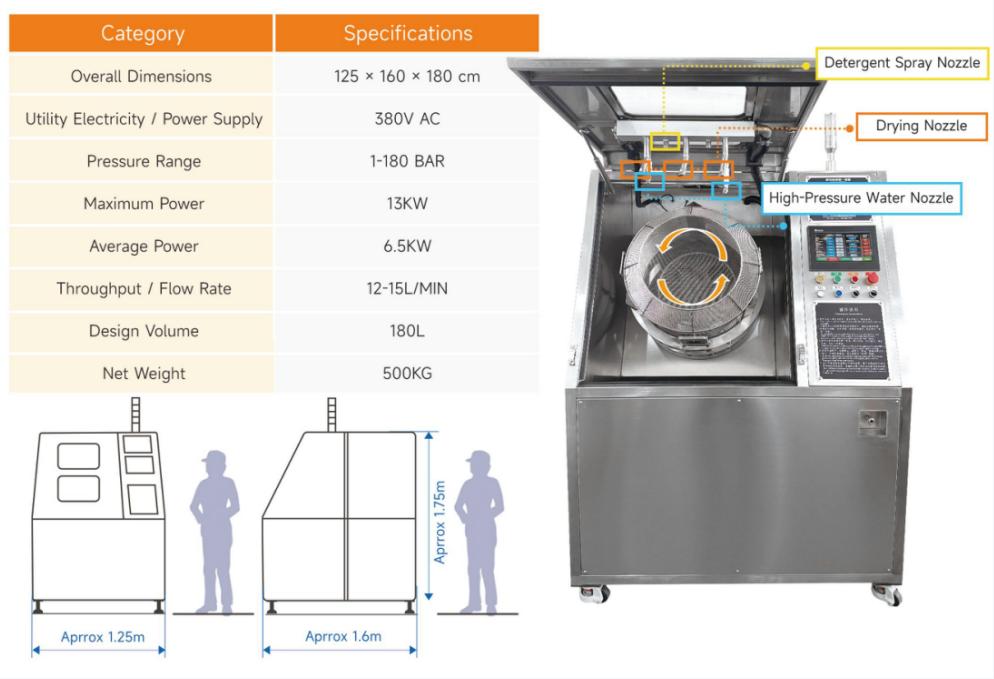

Tailored to the specific challenges of post-deflashing workpieces, the UC-600 delivers targeted cleaning performance. Utilizing multi-angle high-pressure water and air technology, it effectively removes deflashing media dust, oils, and other residues from complex surfaces and intricate geometries, ensuring that components meet the cleanliness standards required for subsequent production stages.

While prioritizing efficiency, the UC-600 is also engineered for operational economy. Its high-speed dehydration system, combined with dual-mode cold and hot drying, ensures rapid and thorough drying with minimal resource consumption—using only 10–15 liters of water per cycle—significantly reducing water, energy, and overall operational costs.

Reliability and stability form the foundation of the UC-600. Equipped with an intelligent PLC control system, it guarantees precise and consistent process parameters, while its robust all-stainless-steel construction ensures long-term durability in demanding industrial environments. The machine supports continuous, stable operation to meet tight production schedules.

The UC-600 features a sealed independent chamber design, ensuring batch integrity and preventing cross-contamination. This makes it particularly suitable for precision component manufacturing where strict cleanliness control is essential.

The launch of the UC-600 marks an extension of STMC’s value chain beyond its core cryogenic deflashing solutions, reinforcing the company’s commitment to helping customers build more efficient, complete, and controllable precision post-processing production lines.

Post time: Feb-02-2026