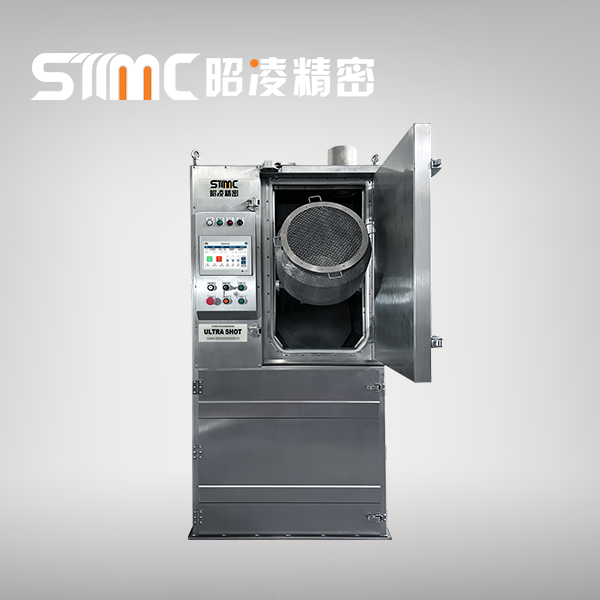

Automatic automotive seal cryogenic deburring machine Ultra Shot NS-60T

Detailed Display

Cryogenic deflashing machine 60T

Cryogenic deflashing machine 60T

Cryogenic deflashing machine core part options

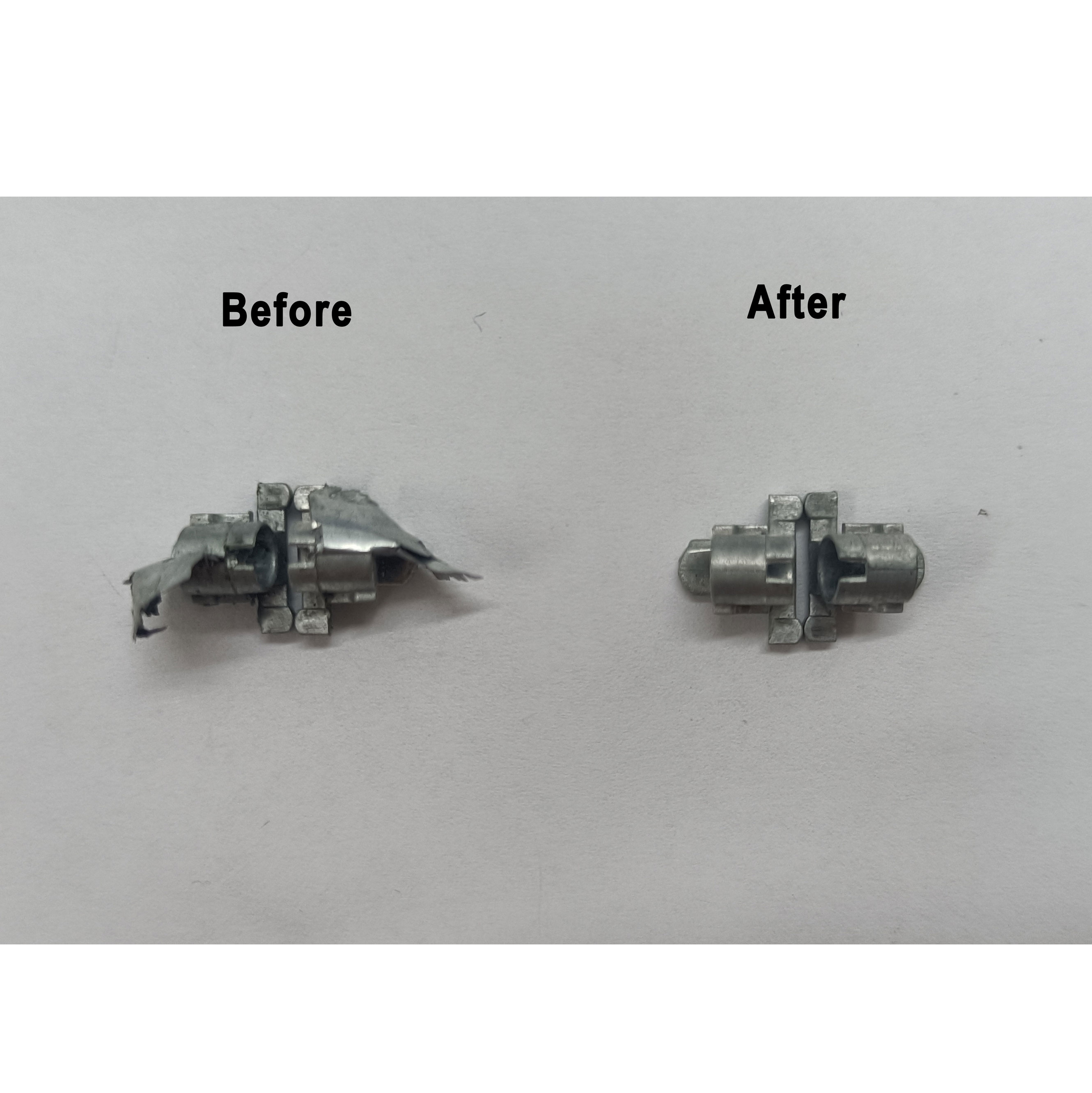

Product Introduction

Advanced technology

1. Full stainless steel frame ensures longer working life of the machine.

2. High efficient designed basket with the OBD system fully reflects high efficiency, energy conservation, environmental protection.

3. Multiple safety control to ensure safe and reliable operation.

Dynamical system

1. The power system uses high-strength metal projectile wheel and Japanese imported high-frequency motor working with the 60/45 degree inclined cylindrical basket.

2. Power output and product processing capacity reach a stable ratio of 1:1.

3. The optimal power ratio produces extraordinary processing accuracy.

Sorting system

1. The machine adopts Sato type anti-plugging, adjustable 3D variable linear waveform vibrating screen.

2. Excellent thermal insulation performance to prevent external icing.

3. Fast and easy disassembly and maintenance, improve production efficiency.

4. Long performance life with high stability.

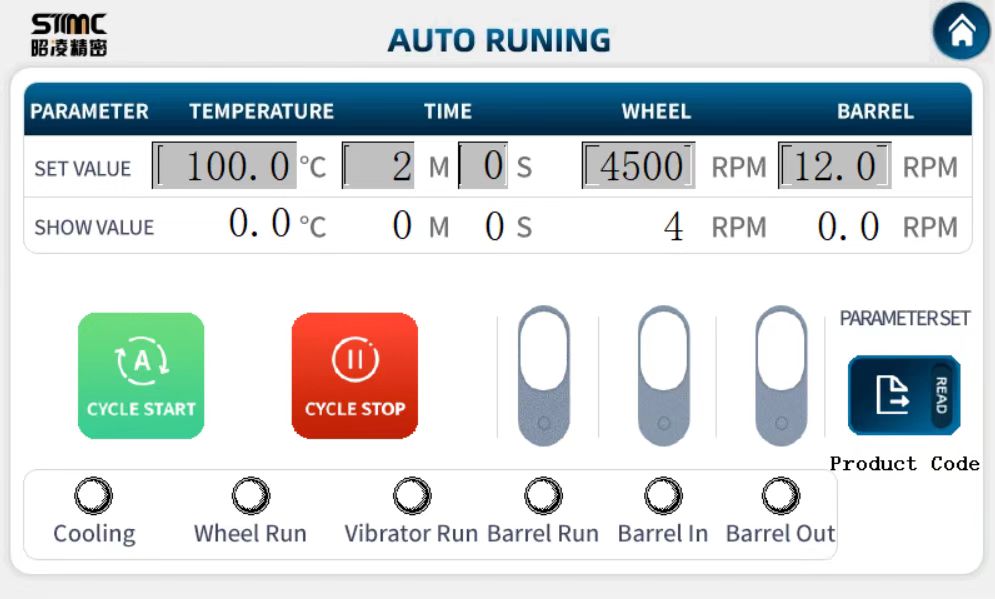

Operating Software Interface

Home Screen

Operating Main Screen

Automatic Mode

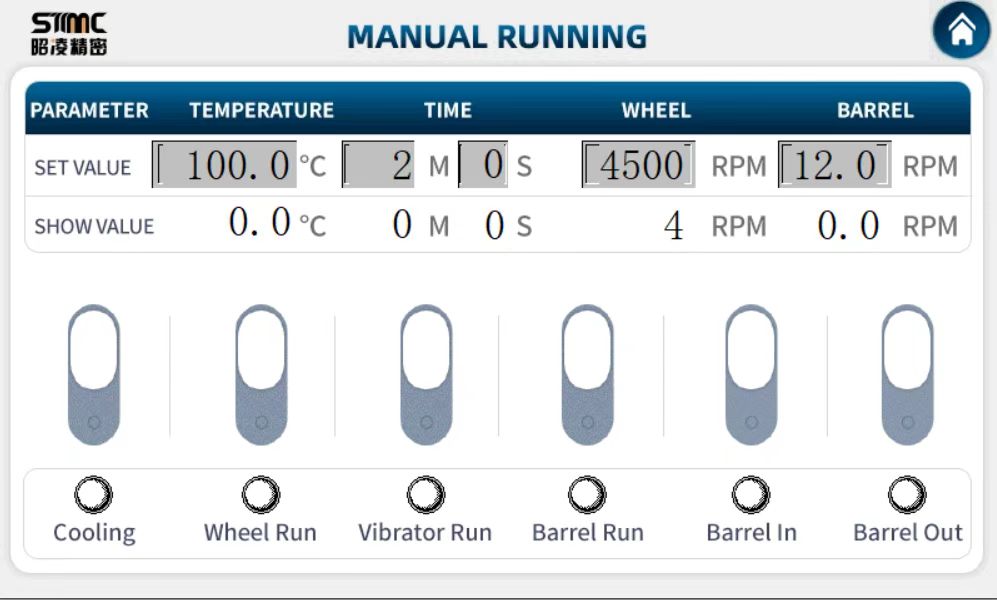

Manual Operating Mode

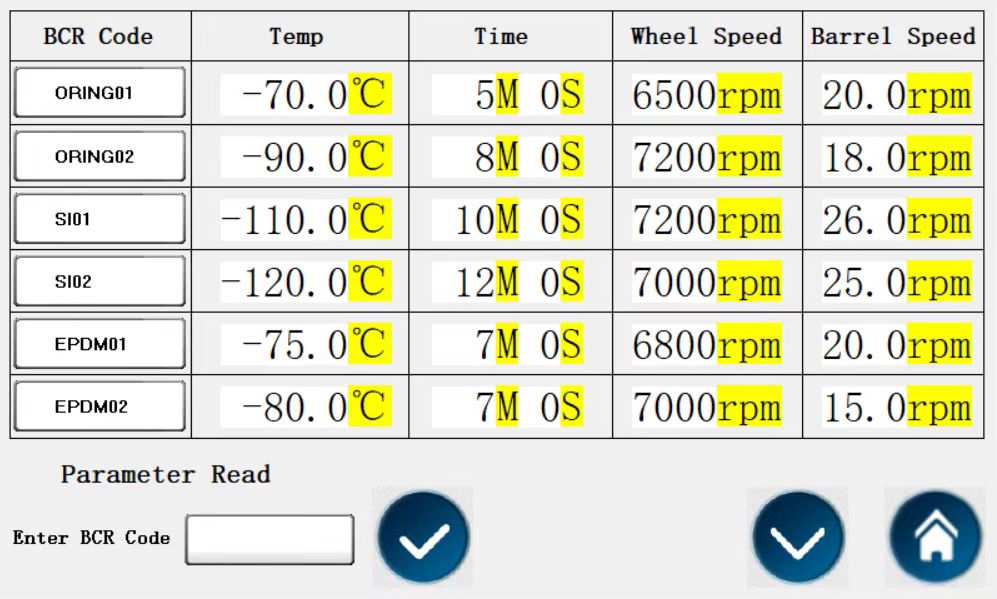

Parameter Save / Read

Parameter Library

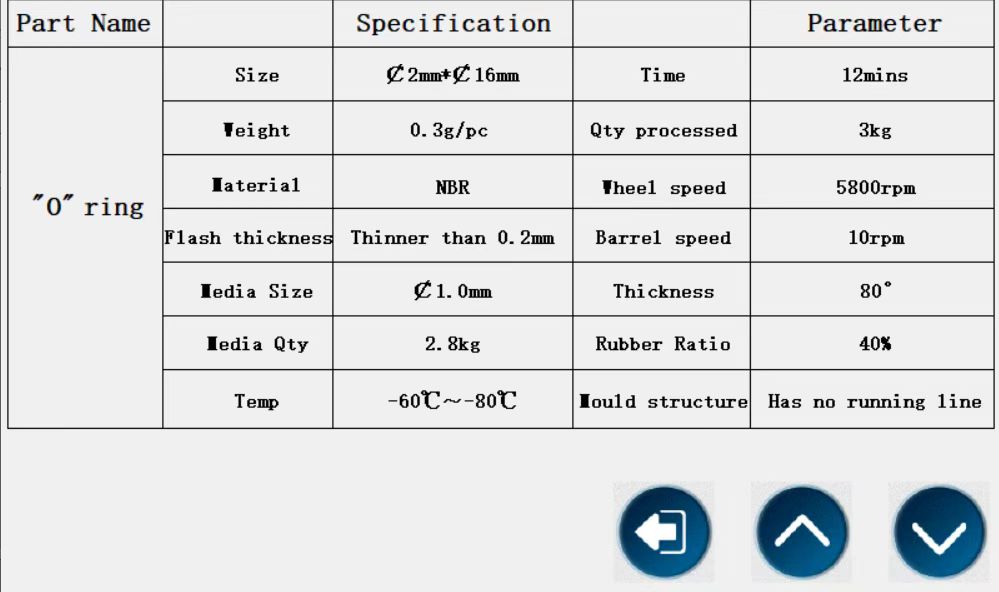

Application

The cryogenic deflashing machine provides users with a solution to efficiently deal with product flash, which is very suitable for large quantity production, parts with various sizes, structures, or materials that require high accuracy for product surface treatment.

1. Rubber and plastic parts.

2. Exceptional ideal for 'O' rings.

3. Flash removal of elastic material products.

4. Electronic components.

5. Medical supplies.

Cryogenic deflashing method is commonly used in the automotive, aerospace, medical, electronics and general rubber industry.

STMC Advantage

1. Brand origins

Originated from Japan's Showadenko Group 30 years of technology precipitation, 16 years of domestic manufacturing experience.

2. Competitive cost

Excellent thermal insulation performance reduces the waste of liquid nitrogen. PIR insulation layer with better thermal insulation performance plus ultra-low temperature solenoid valve to reduce waste of liquid nitrogen and the operating cost.

3. Mature technical solution

All technical specifications are optimal designed including the projectile speed, projectile angle, basket shape, inclination angle and rotation, etc.

4. More effective performance

The parts inside of the projectile circulation system are well sealed which makes the projectile system more powerful and the circulation more stable.

5. Reliable safety protection

The special door hinge on the machine can bear 0.5Mpa pressure. STMC uses special door handle imported from Japan on all cryogenic deflashing machine models which not only greatly simplify the opening of the chamber but also safer and reduce the consumption of liquid nitrogen.

6. High configuration core parts

The default core components are imported from Japan which have better performance and quality, they can also be replaced if German configuration is preferred, including Siemens motors (optional), frequency converter, PLC and touch screen.

7. Quality management

ISO9000 quality management, over 800 incoming inspection, 30 assembling inspections, and 25 delivery inspections.

8. Full service

Free pre-sales test and provide test report (including molding adjustment suggestions), provide the best technical solution, 1 year (up to 2000 hours) warranty, spare parts guarantee supply for 10 years, remote response in less than 2 hours, 48 hours on-site service, 4 return visits per year.