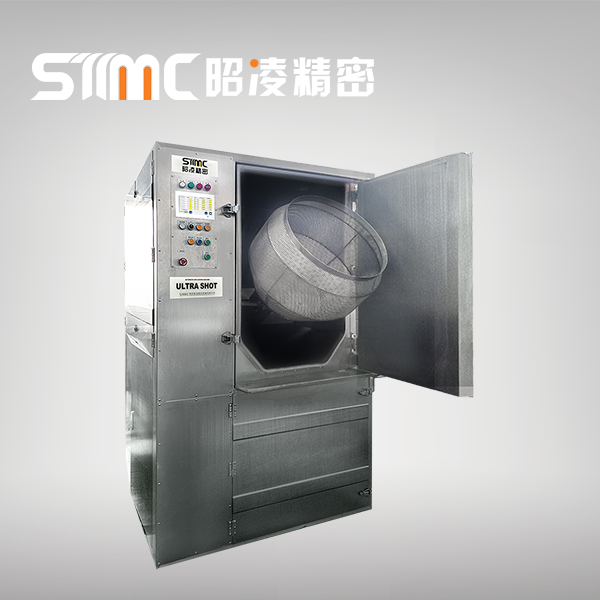

Automatic NBR product cryogenic deburring machine Ultra Shot NS-180T

Detailed Display

Cryogenic deflashing machine 180T

Cryogenic deflashing machine 180T

Cryogenic deflashing machine core part options

Product Introduction

Advanced technology

1. Full stainless steel machine frame ensures an ultra long working life.

2. High efficient designed basket with the OBD system fully reflects high efficiency, energy conservation, environmental protection.

3. Man-machine interaction through touch screen.

4. Alarm query and malfunction prompt can help users to find machine problems more quickly through graphic information and automatically record the failure logging,therefore to facilitate regular maintenance of machine and ensure that the machine is always in the best performance state.

5. Built-in machine operation guide to help operators shorten the learning time of the machine.

6. Built-in troubleshooting guide, which can provide guidance to help operators and maintenance personnel to locate problem.

Dynamical system

1. The power system uses high-strength metal projectile wheel (dual projectile wheel optional) and Japanese imported high-frequency motor working with the 60/45 degree inclined cylindrical basket (special designed basket available optional).

Sorting system

1. The machine adopts Sato type anti-plugging, adjustable 3D variable linear waveform vibrating screen.

2. Excellent thermal insulation performance to prevent external icing.

3. Fast and easy disassembly and maintenance, improve production efficiency.

4. Long performance life with high stability.

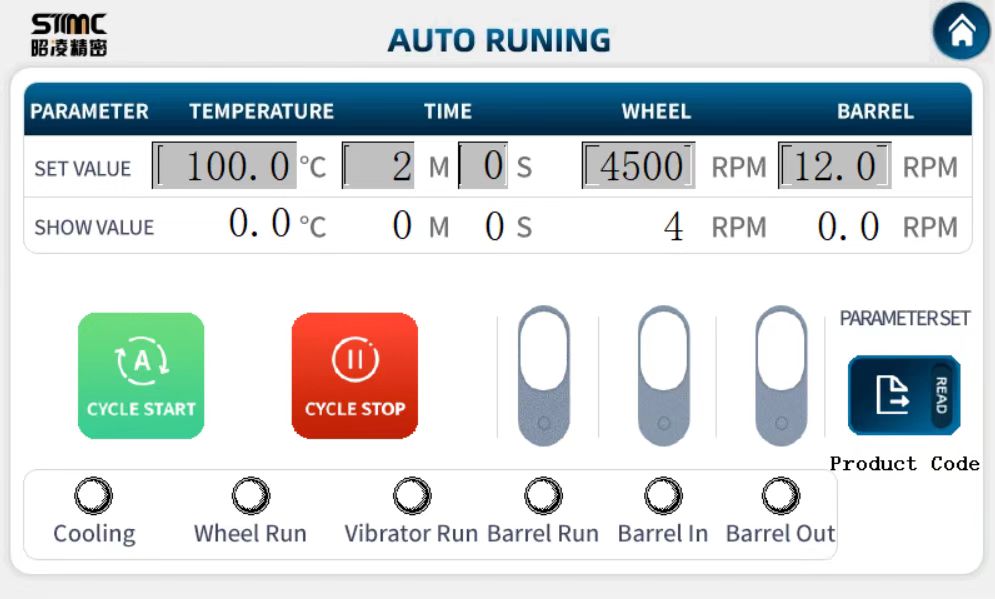

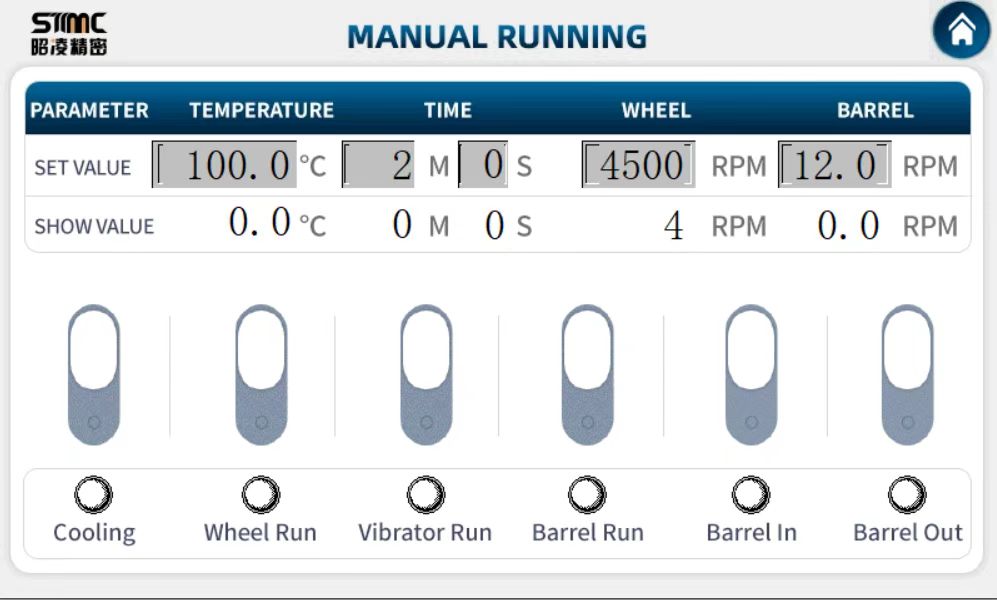

Operating Software Interface

Home Screen

Operating Main Screen

Automatic Mode

Manual Operating Mode

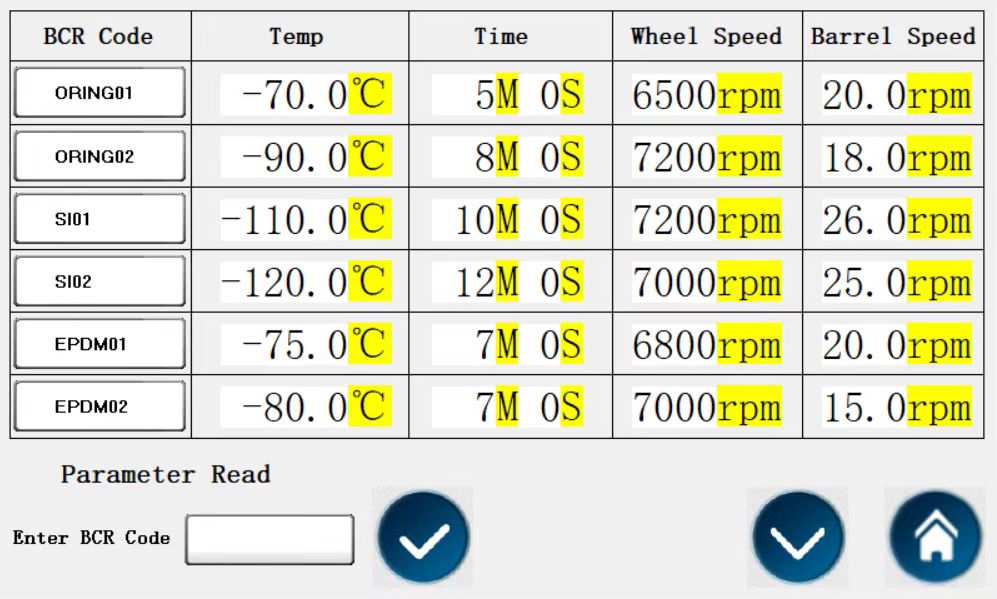

Parameter Save / Read

Parameter Library

Application

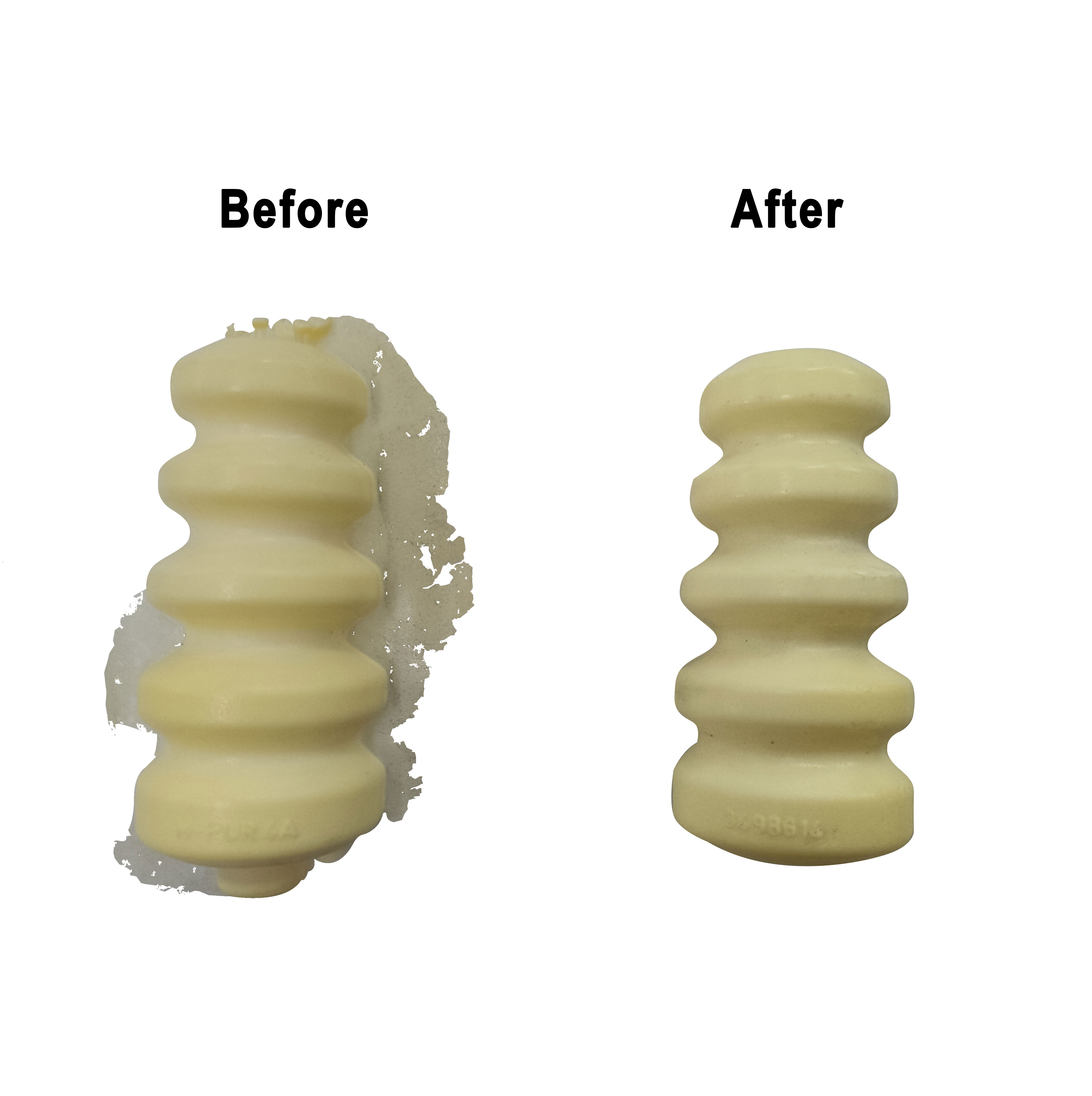

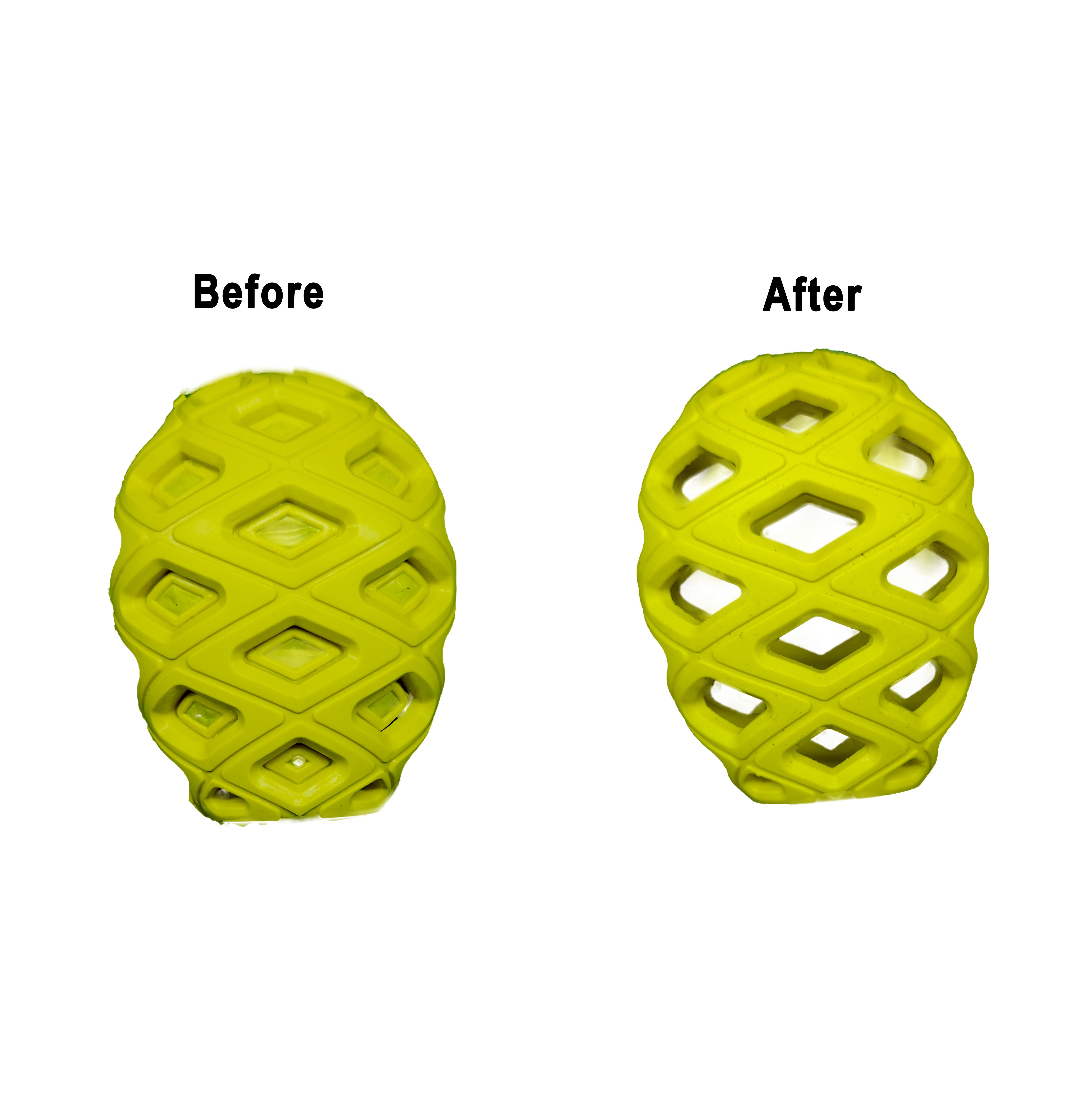

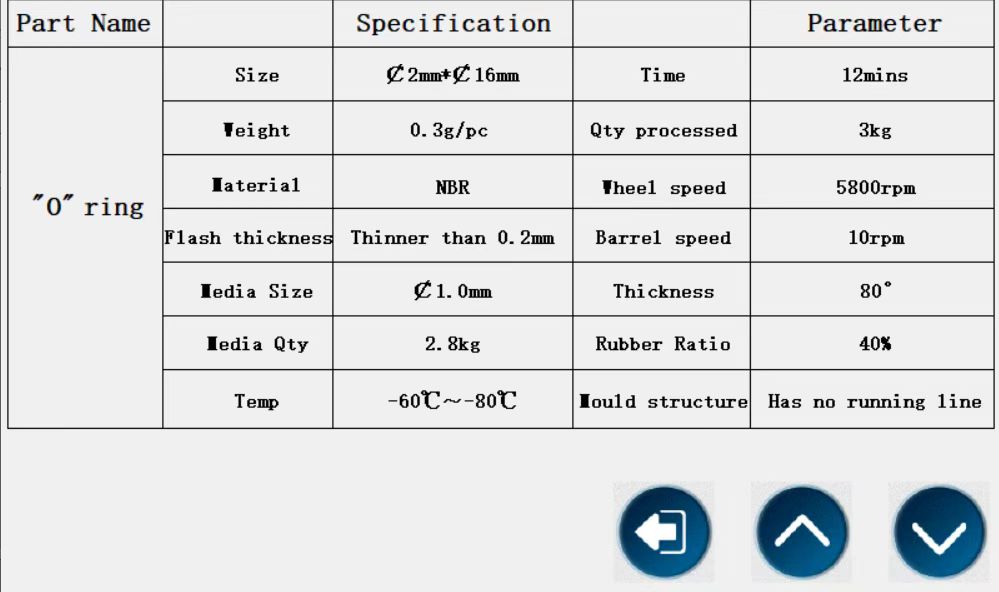

Ultra Shot 180 series cryogenic deflashing machine provide users with efficient solutions for handling product flanges, which are very suitable for mass production, large size parts or groups requiring high surface treatment accuracy.

1. Silicone insole.

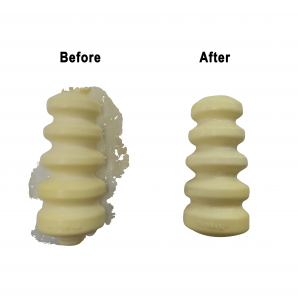

2. Damping block edge repair.

3. Large size elastic material products.

OEM Profile

For clients that are preparing to apply cryogenic deflashing, STMC can provide process testing and professional analysis report for various products and provide viable plan & design base on the on-site condition.

STMC is able to arrange experienced engineers to provide on-site professional training and technical guidance for client operators regarding safe operation, parameter optimization, daily maintenance, and trouble shooting.

STMC has cryogenic deflashing process centers in East region(Nanjing), South region(Dongguan) and west region of China (Chongqing) to provide cryogenic deflashing testing and OEM services.

At the same time, STMC also provides machine renovation and upgrade service to various brands or specifications of cryogenic deflashing machine in order to help clients with machine-performance upgrade.