Case Share

-

Say Goodbye to Rough Edges! STMC Offers Cryogenic Deburring Services for PU Shock Absorbers

Today, parts need to be more precise. Traditional trimming methods often can’t meet the high standards for polyurethane (PU) shock absorbers. To solve this, STMC now offers cryogenic deburring services for PU shock absorbers. We use advanced technology to help improve your product quality. ...Read more -

STMC Successfully Tests Cryogenic Deflashing for NBR O-Rings, Helping Overseas Client Save Costs

STMC recently completed a cryogenic deflashing test for a variety of nitrile (NBR) O-rings sent by an overseas client. The products came in four different sizes and were originally produced using tear-trim molds. While suitable for manual trimming, these molds result in thicker flash grooves and ...Read more -

News Release: STMC Sets New Standard for PPS Injection Molded Part Finishing with Advanced Cryogenic Deflashing Technology

PPS, a high-performance engineering plastic valued for its excellent heat resistance, chemical resistance, and mechanical strength, is widely used in manufacturing precision components for automotive, electronics, aerospace, and other industries. However, its high rigidity and strength make the f...Read more -

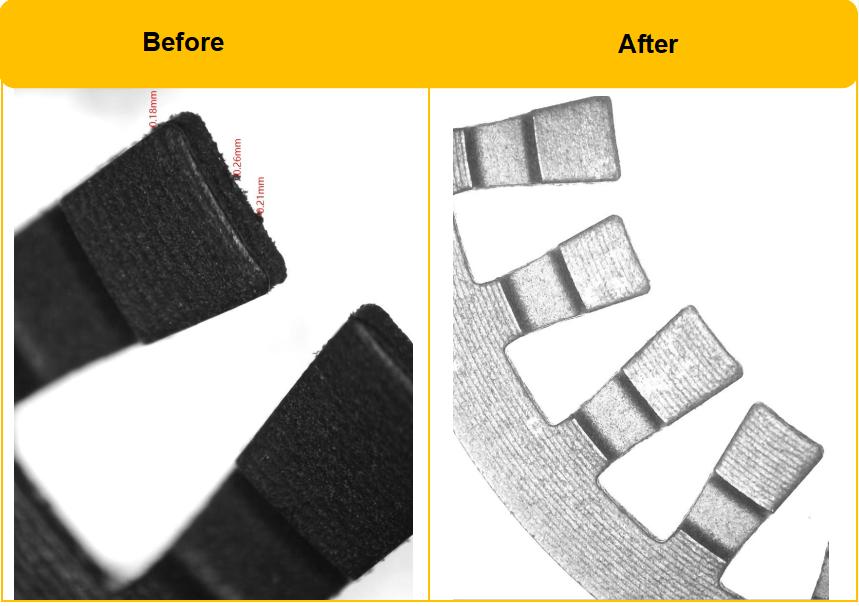

STMC: Efficient Cryogenic Deflashing for Polyurethane Gears

STMC brings two decades of dedicated expertise in cryogenic deflashing technology, integrating R&D, manufacturing, and sales to offer complete solutions, including professional deflashing services. A recent application involved deflashing a batch of polyurethane sun gears for a customer. The ...Read more -

Got a Troublesome Zinc Alloy Toy Car with Flashes? See How STMC Delivered a Perfect Finish

Recently, STMC received a special “test case”—a sample zinc alloy toy car from an overseas client. The challenge was clear: address the problematic flashing, particularly along the parting lines and gate areas. The client’s goal was to find a high-efficiency, non-destructive fin...Read more -

How can burrs on plastic gears be removed?

In the injection molding industry, the quality of molded parts is crucial. This is especially true for precision molded gears, as their quality directly impacts the performance and stability of the entire mechanical equipment. However, removing internal burrs from these precision gears has long b...Read more -

How to Remove Flash from NBR Rubber Rings at the Parting Line?

Nitrile rubber (NBR) is widely used in precision sealing components for automotive, medical, and electronics industries due to its excellent oil resistance, wear resistance, and elasticity. However, under 60x electron microscopy, micro-flash at the parting line remains a persistent issue. Tradit...Read more -

Struggling with EPDM O-Ring Burrs? Try Cryogenic Deflashing/Deburring!

Recently, STMC efficiently completed a cryogenic deflashing/deburring project for a batch of high-precision Ethylene Propylene Diene Monomer (EPDM) O-rings. The client had stringent requirements for surface smoothness and dimensional accuracy, which conventional trimming methods struggled to meet...Read more -

Can Cryogenic Deflashing Achieve Zero Burr Residue on PPS Injection Molded Parts?

Recently, our company successfully completed a freeze deburring project for a high-precision PPS injection molded part. The part had micron-level burrs in its holes and gaps, clearly visible under a 60x electron microscope. Using advanced freeze deburring technology, all burrs were complet...Read more -

STMC Cryogenic deflashing Technology Effectively Solves Flash Removal Challenges for Natural Rubber Pet Toys, Enhancing Product Quality and Production Efficiency

Recently, STMC provided cryogenic deflashing and processing services for a pet toy manufacturer, successfully treating a batch of 200kg rubber pet toys. The product, made of natural rubber, features an internal design that allows for snack filling, with treats slowly released through small holes ...Read more -

How to trim rubber O-rings?

The product being tested today is a EPDM rubber O-ring, with burrs at the mold joint. The product has a small volume, as shown in the right image compared to a coin.Before cryogenic deflashing, we first weigh the product and put it in batches. The current testing machine model is 60C, and the ent...Read more -

STMC’s Cryogenic Deflashing Technology Successfully Removes Flashes from Silicone/FKM Watch Bands, Earning High Praise from International Client

Today, STMC’s technical team successfully completed cryogenic deburring tests for a renowned international watch strap manufacturer. Utilizing its self-developed NS-120T Cryogenic Deflashing Machine, STMC efficiently removed parting lines and micro-hole flashes from silicone and fluorocarbon rub...Read more