Ultra Shot NS-120C Cryogenic Deflashing/Deburring Machine for Rubber, Polyurethane, Silicone, Plastic, Die-casting and Metal Alloy Products

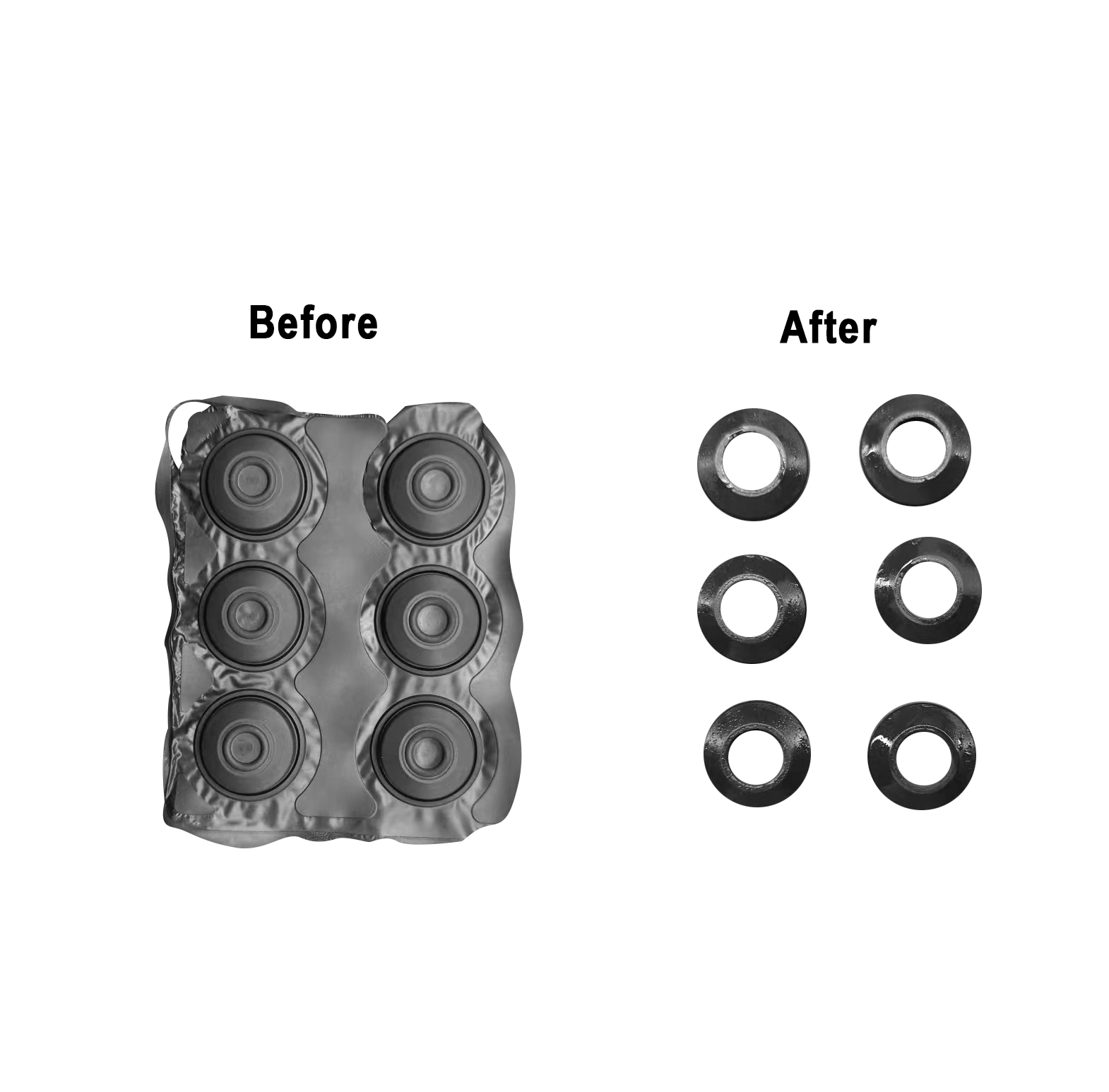

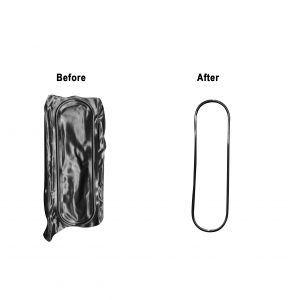

Detailed Display

Cryogenic deflashing machine 120C

Cryogenic deflashing machine 120C

NS-120C operation panel

Advanced Technology

1. Man-machine interaction through touch screen.

2. Preinstalled emergency service contact, convenient for users to get technical support from the manufacturer (STMC).

3. Built-in common product processing parameter guide and product processing difficulty solutions, can better help the operators to find the best processing parameters for different products.

4. Alarm query and malfunction prompt can help users to find machine problems more quickly through graphic information and automatically record the failure logging,therefore to facilitate regular maintenance of machine and ensure that the machine is always in the best performance state.

5. Built-in security settings to prevent unauthorized personnel operating the machine.

6. Built-in machine operation guide to help operators shorten the learning time of the machine.

7. Built-in troubleshooting guide, which can provide guidance to help operators and maintenance personnel to locate problem.

8. BCR parameter modification and storage, can reduce the manual adjustment of parameters in the process,save time and improve production efficiency.

Application

Ultra Shot 120 series cryogenic deflashing machine is an efficient product surface treatment equipment, suitable for mass production, fewer varieties and high requirements of product surface treatment accuracy of the enterprise, can help enterprises to achieve efficient production. The traditional trimming method requires manual operation, which takes a long time and is prone to errors. Using this machine can greatly reduce labor cost and production cost while ensuring quality.

1. Most rubber products, including rubber shaped parts.

2. Closed "O" ring.

3. Remove flying edges of elastic material products.

4. Deal with flying edges of injection parts.

Department Setting

Nowadays, STMC has setted R&D center, Display and testing center, marketing department, OEM center, quality management department, manufacturing center, Chongqing branch, Dongguan branch and so on.