Cryogenic Deburring Process Explained: Benefits, Tools, and Applications

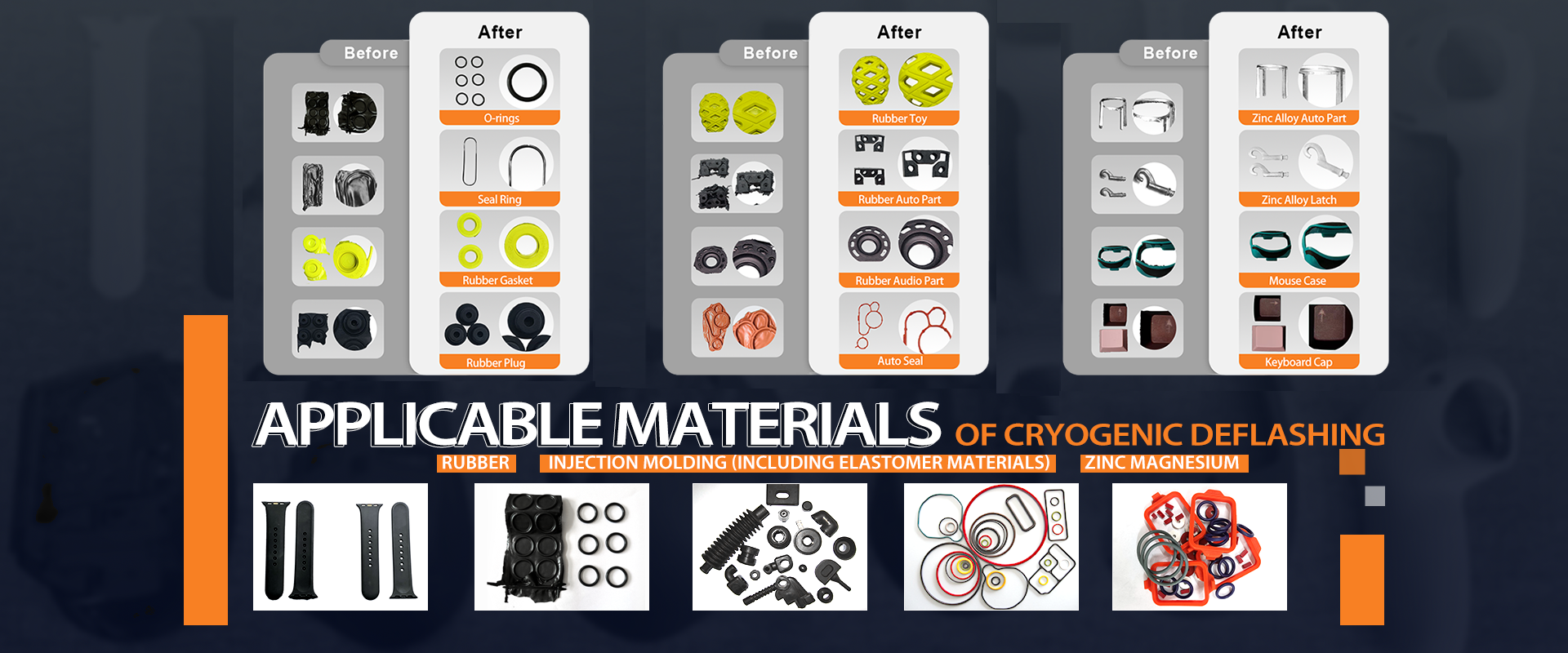

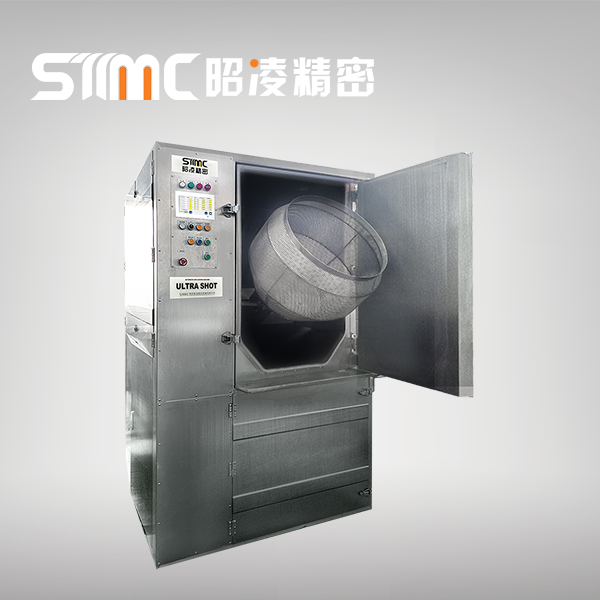

Introducing the innovative Cryogenic Deburring Process, revolutionizing the realm of machining and manufacturing. Developed by Showtop Techno-machine Nanjing Co., Ltd., a leading China-based manufacturer, supplier, and factory of advanced machining solutions, this cutting-edge technology ensures unparalleled precision and efficiency in deburring operations. Our Cryogenic Deburring Process utilizes the power of extreme low temperatures to remove burrs and imperfections from metal and plastic components, delivering impeccable quality and surface finishes. By subjecting the components to sub-zero temperatures, this process causes the burrs to become brittle and easily detachable, enabling swift and thorough removal. At Showtop Techno-machine Nanjing Co., Ltd., we leverage our expertise and state-of-the-art facilities to tailor the Cryogenic Deburring Process to the exact specifications of our clients. Our skilled team of technicians ensures seamless integration into existing manufacturing processes, maximizing productivity and minimizing downtime. Advantages of the Cryogenic Deburring Process include enhanced precision, reduced material waste, increased tool life, and improved product performance. With this technological breakthrough, Showtop Techno-machine Nanjing Co., Ltd. reaffirms its commitment to providing industry-leading solutions that optimize manufacturing operations across various sectors. Choose Showtop Techno-machine Nanjing Co., Ltd. as your trusted partner for the Cryogenic Deburring Process and embrace a new era of superior quality and efficiency in deburring.

Related Products